AUTOOL HTS709 Dry Ice Cleaning Machine

$3199.00

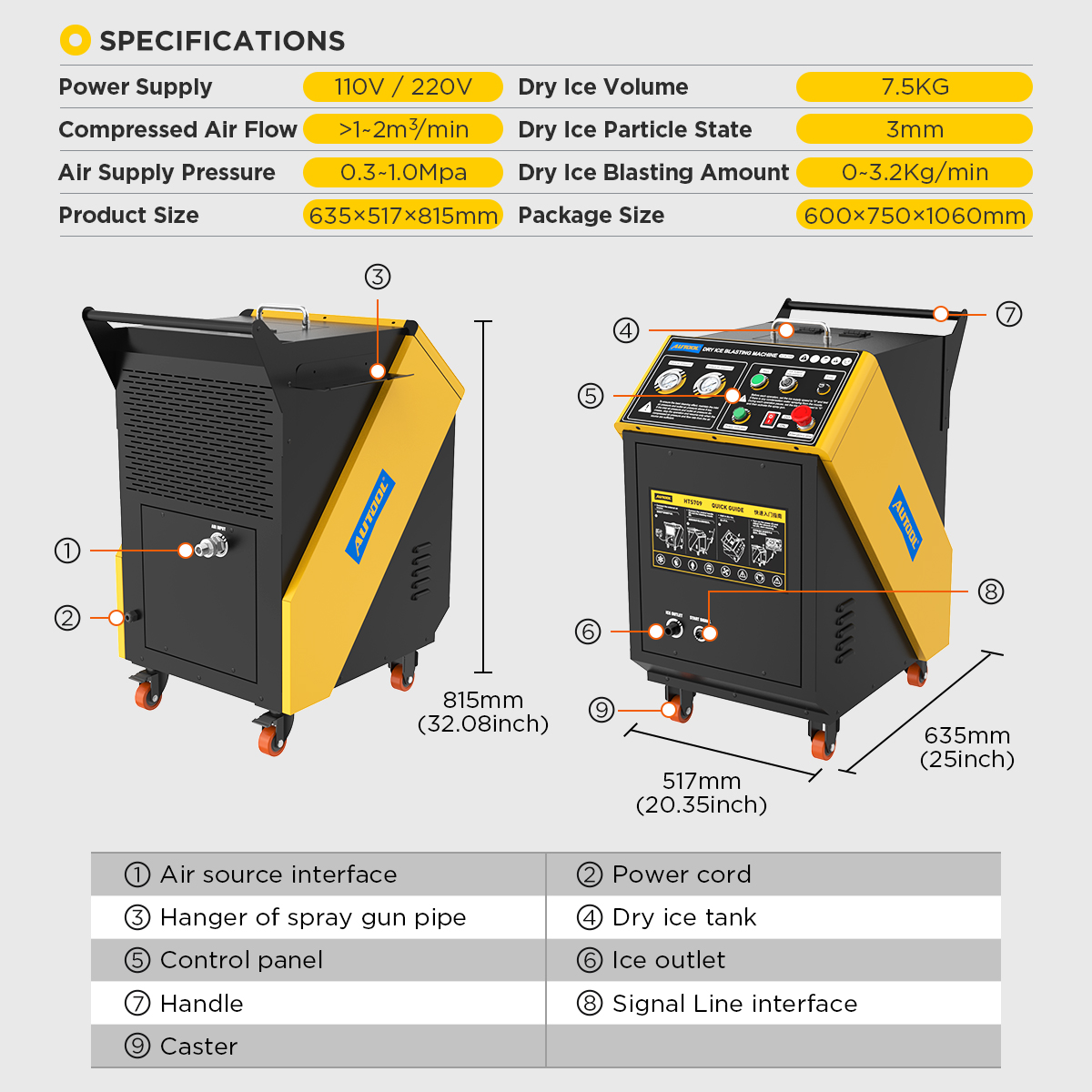

- Dual Pressure Gauge Design: Equipped with both input and output pressure gauges, allowing for precise and safe operation.

- Large Capacity: The machine can hold up to 7.5kg of dry ice internally, extending the continuous operation time of the machine.

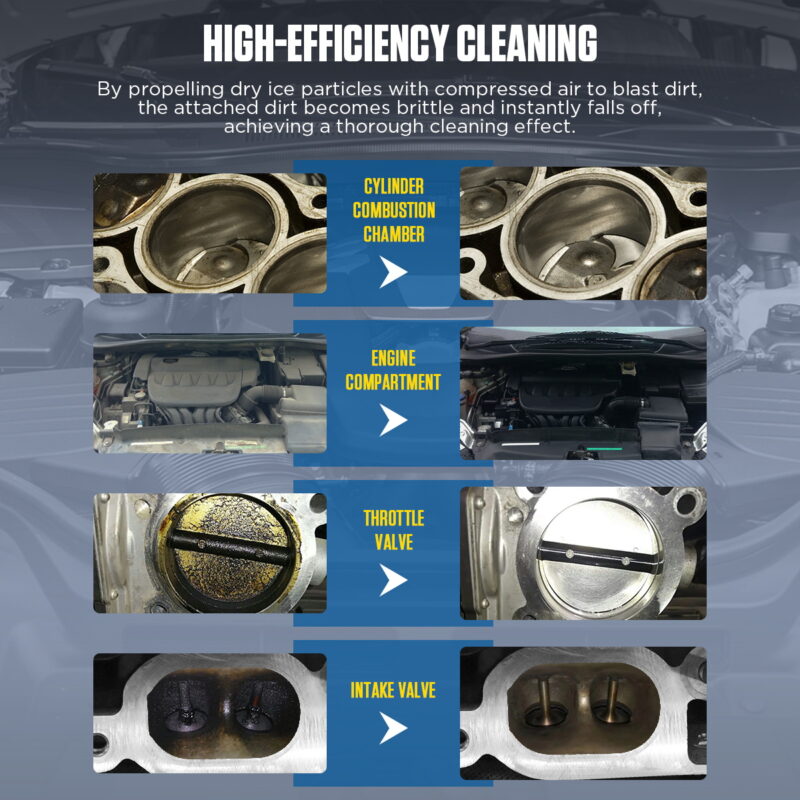

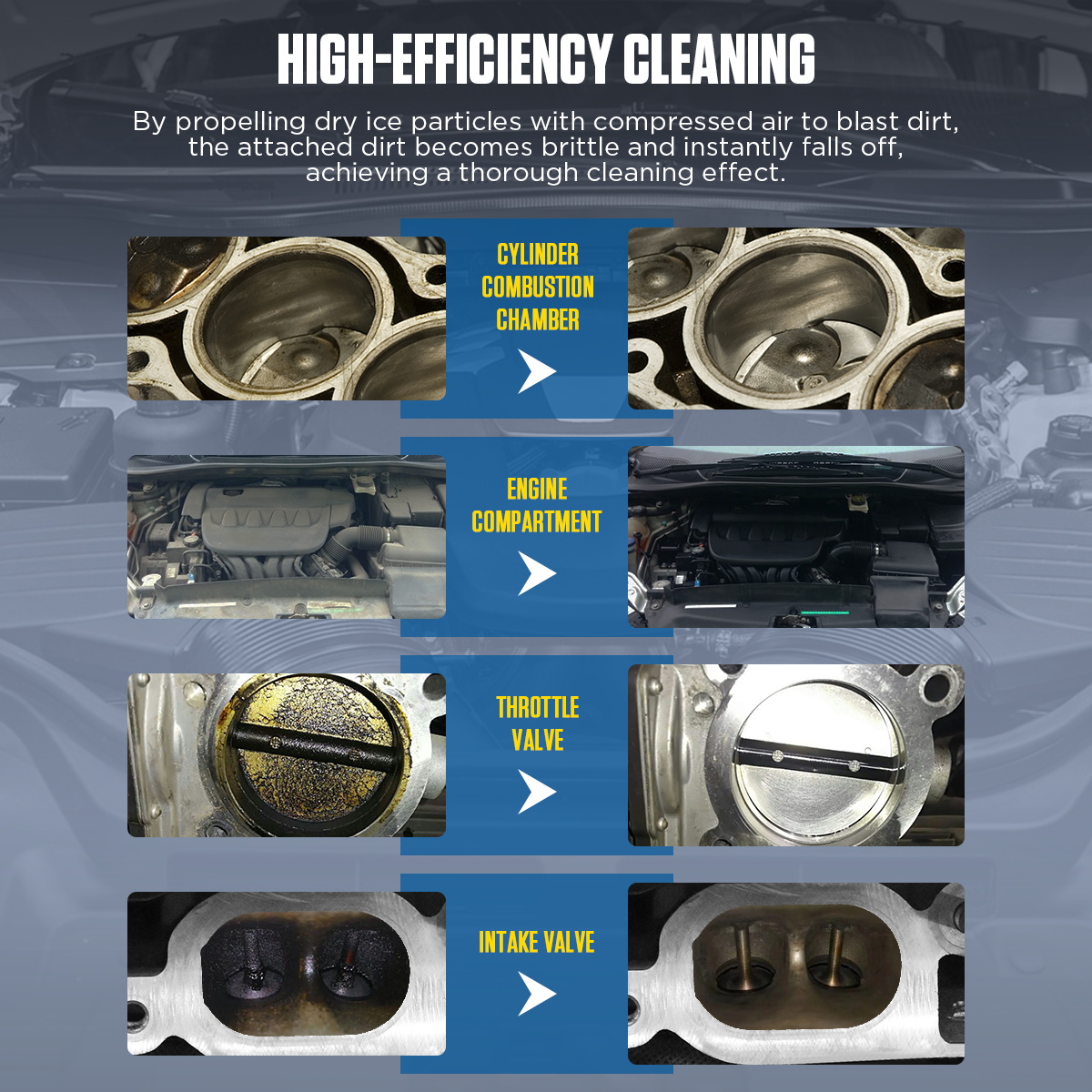

- Efficient Cleaning: No need to disassemble vehicle components. In about 15 minutes, you can thoroughly clean carbon deposits in various vehicle parts.

For wholesale prices and more discounts click here.

Please select the correct warehouse before payment. Such as EU users choosing Germany stock will enjoy free shipping and no customs duties (except Serbia and Cyprus).

AUTOOL HTS709 Dry Ice Cleaning Machine & Dry Ice Blasting

The AUTOOL HTS709 is a high-performance dry ice blasting equipment with dual pressure display functions, specifically designed for carbon cleaning in automotive engines. It accelerates dry ice particles with high-speed airflow, quickly removing carbon deposits from the engine. The dry ice vaporizes rapidly in the air after cleaning, leaving no residue or pollution and causing no damage to the vehicle. The dry ice cleaning machine is particularly suitable for cleaning carbon deposits in areas such as the engine compartment, cylinder combustion chambers, intake valves, throttle valves, and the underside of the vehicle, and can complete the cleaning process in just 15 minutes without requiring disassembly. Compared to other AUTOOL Dry Ice Blaster Machine models, the HTS709 has been further optimized and upgraded to ensure uninterrupted operation with excellent reliability. With its new design, it can start working as long as the air pressure is above 4 kg-f/cm².

- I recommend using 3 mm dry ice pellets and up to 5 mm dry ice pellets.

- The machine requires 90 PSI or more for proper operation.

- Suggest using a 1.5m³/min compressor with a 300L air tank to supply the air pressure and store air pressure in the air tank (It would be better if your air compressor has a dehumidification function, which can effectively prevent dry ice from becoming clumped together).

- The machine doesn’t run on a single phase. The socket must connect with earth wire.

- The blasting hose is 3m.

- Machie’s operating power is more than 1.5m³/min.

- The connection of the air inlet is a female 4-part (1/2) thread with an inner diameter of about 19mm.

- Nozzle sizes are available in 5mm and 6mm.

- We can customize a longer hose for you if need it, the longest hose is 5m. You need to pay extra fees for it. Please get in touch with us for more details.

- The tariff policy varies from country to country, and some countries do not have tariffs while others do. Good news: The tariffs of HTS709 shipped from China to the US can be free, and tariffs for shipping to other countries can also be reduced.

- Because AUTOOL HTS709 has a relatively high shipping cost and also needs to pay certain customs duties, it does not support returns. Please be sure to contact us if there is any problem with the HTS709 or if you have any questions. We will make sure that your problems are well solved, that you receive the best customer service, and are 100 percent happy with your purchase. Thanks 🙂

- Dry ice cleaning offers several key advantages over traditional cleaning methods like chemical solvents, hydrogen-oxygen machines, and walnut blasters. First, it does not require engine disassembly. Second, compared to hydrogen-oxygen machine cleaning, dry ice cleaning is a physical carbon removal process that does not damage sensitive vehicle components such as the catalytic converter. Third, unlike walnut blaster cleaning, dry ice avoids part wear. During the process, carbon deposits rapidly convert to powder when high-pressure air and -78.5°C dry ice particles collide and explode. The treated parts then undergo sublimation and decomposition, expelling impurities through compressed air. This entire process is non-toxic, harmless, and free from secondary pollution.

- The Dry Ice Blasting Machine uses compressed air as its power source to accelerate dry ice particles to supersonic speeds, which are then blasted onto the surface of the object to be cleaned. Unlike cleaning methods that rely purely on the kinetic energy of the dry ice particles, the dry ice blasting equipment also utilizes the extremely low temperature of dry ice to enhance its cleaning effect. When the dry ice particles collide with the surface, they sublimate rapidly upon impact. This process generates a swift heat exchange, causing the solid carbon dioxide in the dry ice to sublimate into gas, expanding nearly 800 times in volume. This rapid expansion creates a “micro-explosion” effect, which effectively removes surface contaminants, resulting in a thorough cleaning.

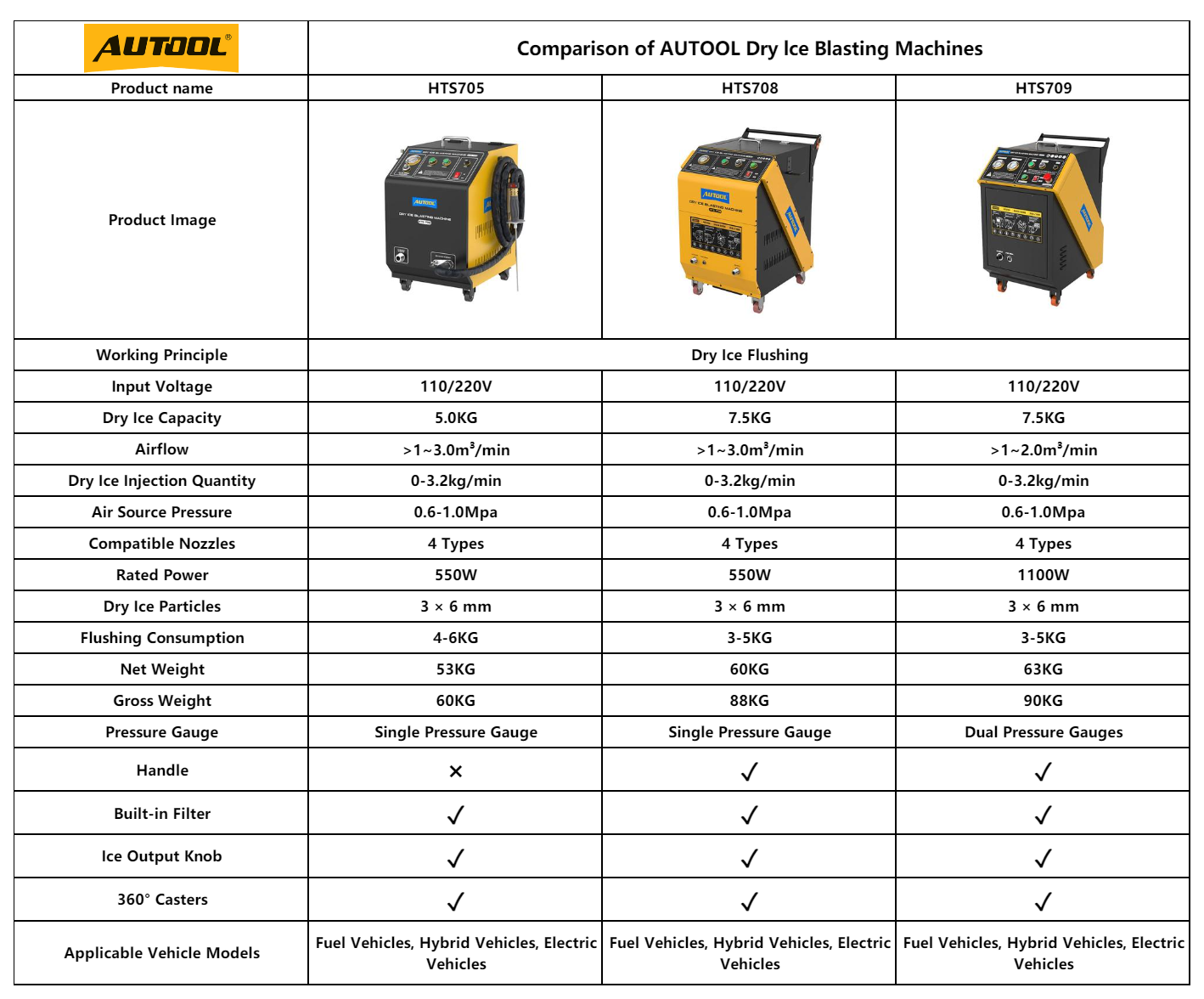

What is the difference between Dry Ice Cleaning Machines?

AUTOOL HTS705 vs. HTS708 vs. HTS709 Dry Ice Blasting Machine Differences?

- AUTOOL HTS705 (Basic Portable Model)

Designed as an entry-level dry ice blaster, the HTS705 emphasizes portability and ease of transport. Equipped with a single pressure gauge for basic monitoring, it offers a 5kg dry ice capacity and a lightweight 60kg package, making it ideal for international shipping. Perfect for individual users or small workshops with low cleaning frequency, the HTS705 delivers a balance of essential performance, cost-effectiveness, and convenient operation. - AUTOOL HTS708 (Standard Professional Model)

Positioned as the main professional model, the HTS708 enhances both capacity and durability. With a 7.5kg dry ice capacity—a 50% increase over the HTS705—it supports medium to high-intensity continuous operation. Featuring a robust, professional-grade body and a single pressure gauge for stable pressure control, this 100kg unit reduces refill frequency and ensures consistent efficiency. The HTS708 is ideal for professional workshops requiring reliable, daily cleaning performance. - AUTOOL HTS709 (Upgraded Flagship Model)

As the flagship model, the HTS709 incorporates a dual pressure gauge system for precise control of jet pressure and flow rate. Sharing the 7.5kg dry ice capacity and 100kg package weight of the HTS708, it is engineered for complex and precision cleaning tasks. With advanced parameter adjustments for enhanced accuracy, the HTS709 represents AUTOOL’s highest technical standard, making it the top choice for professionals handling high-difficulty contaminants or delicate components.

AUTOOL Engine Decarbonizer Machine Quick Search

AUTOOL HTS709 Dry Ice Blasting Cleaning Machine Features:

- Dual Pressure Gauge Design: Equipped with both input and output pressure gauges, allowing for precise and safe operation.

- Large-diameter Oil-Water Separator: Prevents water from entering the dry ice cleaning process, ensuring that the dry ice does not mix with water and form clumps, which avoids issues such as pipeline blockages, water retention in vehicle cleaning parts, and internal water accumulation in the product.

- Large Capacity: The machine can hold up to 7.5kg of dry ice internally, extending the continuous operation time of the machine.

- Spiral Ice Separation Technology: The innovative spiral dry ice separation system continuously stirs to prevent dry ice from sticking together or forming clumps, ensuring smooth delivery of dry ice particles during the cleaning process and avoiding any blockages.

- Control Panel: The built-in smart microcomputer design allows for precise control of pressure and adjustable ice delivery speed, ensuring the cleaning process operates at optimal conditions.

- Efficient Cleaning: No need to disassemble vehicle components. In about 15 minutes, carbon deposits in various vehicle parts (such as the throttle, intake valves, engine components, and cylinder combustion chambers) can be thoroughly cleaned.

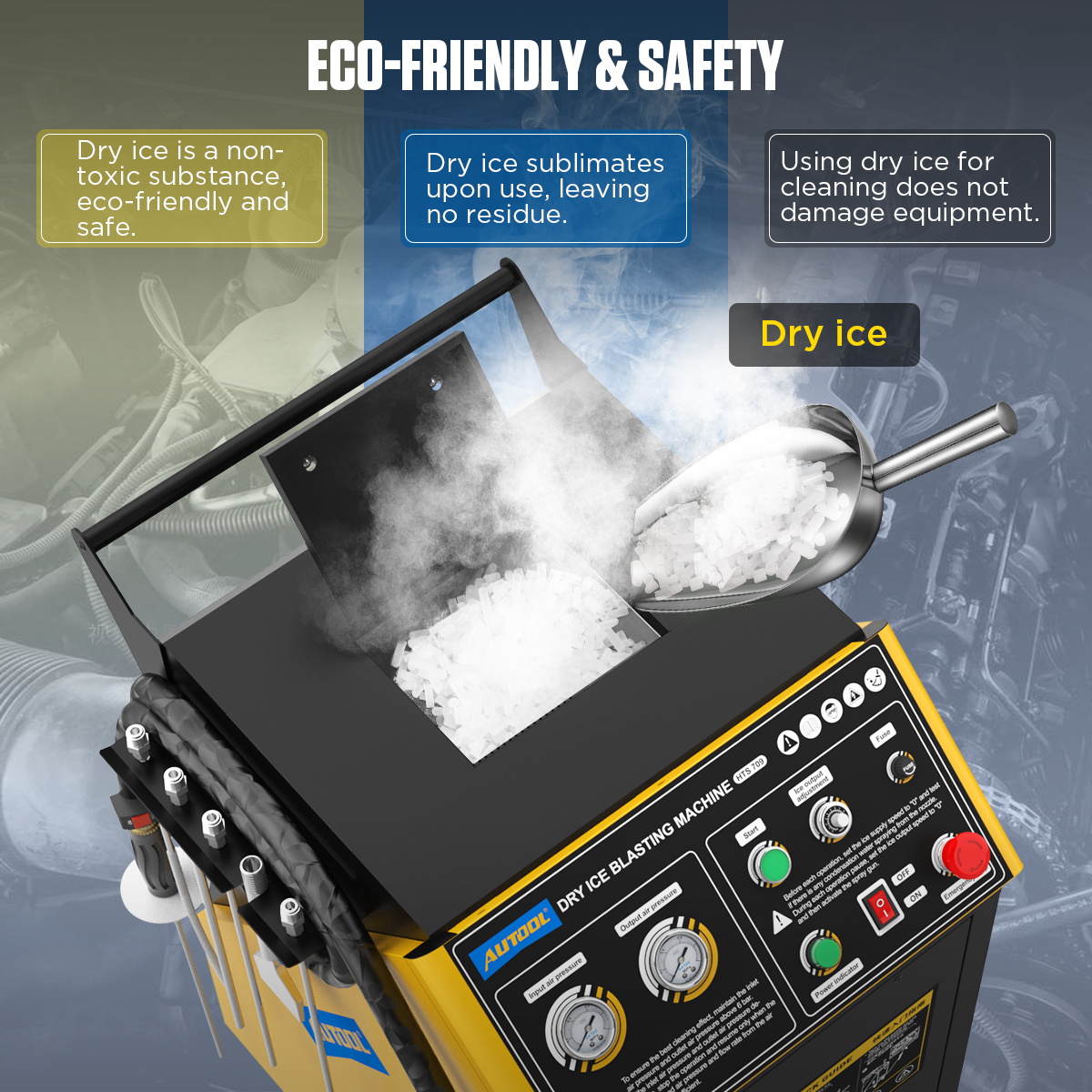

- Safe and Harmless: Dry ice is a non-toxic, harmless substance, ensuring the safe use of the equipment and preventing harm to users’ health.

- Exquisite Design: The dry ice cleaning machine features a push handle, control panel, air source interface, and four universal wheels at the bottom that allow 360° all-around movement, making it convenient and labor-saving.

- Wide Application Range: It is widely used in various industries such as rubber, casting, automotive, shipping, power, chemicals, printing, plastics, food, pharmaceuticals, aviation, and more, not limited to automotive maintenance.

- Three-Year Warranty, Lifetime Maintenance: For damage caused by non-human factors, AUTOOL promises to resend parts for free within 3 years. If you have any problems, please contact us, and we will respond within 24 hours!

Packing List

Dry Ice Cleaning Machine FAQs

Dry ice blasting or dry ice cleaning is an environmentally sustainable cleaning and surface preparation technique.

Like sandblasting, grit blasting, and soda blasting, dry ice cleaning uses a pressurized air stream to clean surfaces. However, it uses recycled CO2 pellets, blasts them at supersonic speeds, and causes them to sublimate on impact to remove dirt and contaminants.

The process is non-abrasive, non-conductive, non-flammable, and non-toxic. It is also chemical-free, and water-free, and does not create a secondary waste stream. When dry ice hits the surface being cleaned, it sublimates, changing from a solid CO2 phase to a gaseous CO2.

Three main factors affect the dry ice cleaning process. These factors are the kinetic energy of the particles, the thermal shock effect, and the thermodynamic effect. To explain the process more easily, we have created the following acronym (ICE).

Impact – The impact of the particles creates a kinetic effect. Compressed air accelerates the soft dry ice at supersonic speed through specially designed nozzles.

Cold – The low temperature of the dry ice pellets creates a thermal effect. The temperature of the dry ice (-109°F / -78.9°C) causes the contaminant to become brittle. This helps to break the bond between the substrate and the contaminant.

Expansion – The expansion of dry ice pellets. Dry ice pellets sublimate on impact, expanding in volume and removing contaminants.

Because of its unique properties, dry ice has many advantages that make it a more attractive cleaning solution than alternatives. Benefits include.

- Cleaning equipment in place with little or no disassembly

- Dry cleaning without the use of water or chemicals

- Reduced downtime associated with cleaning

- Cleaning without secondary waste

- Improved product quality and reduced scrap

- Eliminate equipment wear and tear

- An environmentally sustainable cleaning method

Dry ice blasting requires a simple setup. In addition to the dry ice blaster, the system will equip you with the blasting and air hoses, nozzles, and tips that work best for you.

The only other items required for the operating system are:

- Compressed air source (plant air or air compressor)

- Power supply

- Dry ice supply

If you are using a portable diesel compressor as your air source, an aftercooler may be useful. The aftercooler removes most of the moisture from the system and cools the air to within 15°F (-9.4°C) of the ambient air. This depends largely on the humidity level.

Most of our customers purchase dry ice pellets or blocks from industrial gas suppliers, welding supply companies, and other regional or local suppliers. Dry ice can be purchased on an as-needed basis, or regular deliveries can be arranged to your facility. Regular delivery trucks covering a 100-mile radius are available in most major metropolitan areas. Dry ice can also be shipped using common carriers and delivered in insulated containers.

For manufacturers who regularly require large quantities of dry ice or work in remote areas, we recommend considering a dry ice production machine to meet the high demand.

Dry ice is a commodity, and prices vary by region.

When working with dry ice, ensure proper ventilation and use appropriate personal protective equipment when handling liquid or solid dry ice.

Wear appropriate protective devices such as earplugs, glasses, gloves, and open-toed shoes when operating a dry ice blaster

Dry ice blasting effectively removes failing or weakly bonded paint, but its mild-medium strength may not always be enough. Factors like paint adhesion, type of paint, and primer affect its success. In some cases, even high-pressure blasting can be too slow or ineffective.

Dry ice blasting alone will remove any loosely adhered rust, surface rust, oxidation, and salt (SP 6), but it will not remove deeply adhered or pitting oxidation. Due to the non-abrasive nature of dry ice, it is not sufficient to create contoured or white metal finishes.

When following IAQA standards, dry ice blasting removes 99.9% of mold spores faster than traditional cleaning methods. The process eliminates timely manual cleaning without secondary waste, resulting in reduced mold remediation time, and lower total labor costs and project time. The dry ice blasting process uses no chemicals and can deodorize the affected area.

Dry ice blasting leaves no residue or waste. Dry ice sublimates on impact to clean automotive surfaces without creating secondary waste, residue, or moisture. This eliminates additional cleanup, disposal of secondary waste streams, and additional cleaning preparation, such as masking delicate sensors or wrapping electronic components before cleaning. This significantly reduces the duration of cleaning projects and the resulting downtime.

Eliminating secondary waste also allows the equipment to be cleaned both in-line and while still in operation.