AUTOOL CT200 Injector Ultrasonic Cleaner & Tester

$319.00

- Advanced technology: combining ultrasonic cleaning technology and microprocessor hydraulic control cleaning detection technology.

- Multifunctionality: 3 cleaning functions, and 9 detection functions, can meet most of the cleaning and testing requirements.

- After-sales Service: Three-Year Warranty, Lifetime Maintenance. Online Support>>

For wholesale prices and more discounts click here.

Please select the correct warehouse before payment. Such as EU users choosing Germany stock will enjoy free shipping and no customs duties (except Serbia and Cyprus).

AUTOOL CT200 Injector Ultrasonic Cleaner and Tester machine is designed with wide voltage technology and is suitable for 110V and 220V voltage.

-

For ultrasonic cleaning fluid, please use professional engine carbon cleaning fluid.

-

Please use professional injector test fluid, do not use corrosive cleaning fluid, the cleaning fluid will damage the equipment, if you use the cleaning fluid to damage the equipment when testing the injector, you need to bear the repair cost.

-

When using the ultrasonic cleaning function, please add the transmitter carbon cleaning fluid before running the equipment, please do not add the cleaning fluid directly to open the equipment to run, as it will lead to ultrasonic motherboard damage.

-

How to choose cleaning fluid? In order to achieve the best cleaning effect, it is recommended to use a professional syringe ultrasonic cleaning fluid to clean the injector. Or you can use medical alcohol with an alcohol content of more than 75% instead of cleaning fluid, but the cleaning effect may not be good enough.

-

How to choose test fluid? In order to achieve the best test effect, it is recommended to use professional automotive injector test fluids. If it is not available locally, use medical alcohol with an alcohol content of more than 75% as an alternative to the test fluid.

-

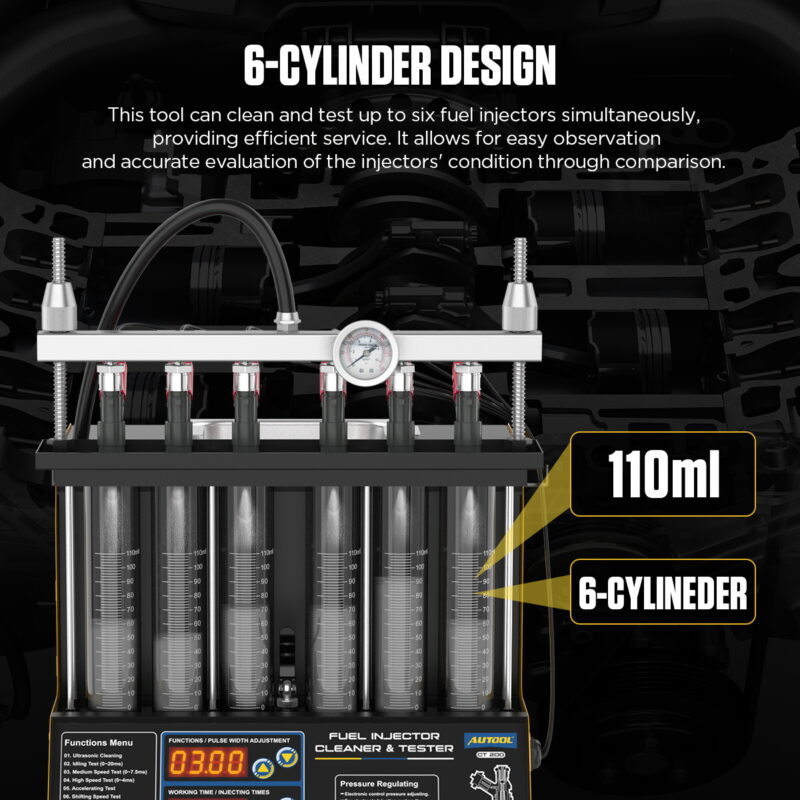

When you test a single injector you simply need to plug only the other 5 cylinders, so the CT200 comes with five plugs.

What is the Difference Between the AUTOOL Fuel Injector Cleaner & Tester Machine?

FAQs

- 1. Cylinder Testing Capacity

The FN608 supports testing for 8 cylinders, while the FN606 supports testing for 6 cylinders.

- 2. Pump Configuration

The FN608 is equipped with two independent fuel pumps, each corresponding to a separate fuel rail (left and right). Both pumps operate independently during testing — if one pump fails (e.g., the left pump), only the corresponding fuel rail is affected, while the other continues to function normally. This dual-pump system ensures greater reliability and uninterrupted testing. In contrast, the FN606 uses a single fuel pump; if the pump fails, it stops the entire system until the pump is replaced.

- 1. Cylinder Testing Capacity

The FN608 supports testing for 8 cylinders, while the CT500 supports testing for 6 cylinders. This makes the FN608 more suitable for high-capacity or multi-cylinder engine injectors.

- 2. Heating Function

The FN608 features a heating cleaning tank capable of maintaining a constant temperature up to 50°C, which significantly improves cleaning efficiency and performance. In contrast, the CT500 does not support heating, offering a more basic cleaning function.

- 3. Voltage Settings

The FN608 supports multiple voltage ranges — 12V, 12–70V, and 120–180V — making it compatible with a wider variety of injector types. The CT500, however, supports only 12V, 70V, and 120V, providing more limited voltage adaptability.

- 4. Cleaning Tank Design

The FN608 allows users to operate the cleaning tank independently or together with the main unit, offering greater flexibility for maintenance and cleaning. In contrast, the CT500 integrates the cleaning tank into the main body, so users cannot operate it separately, which limits independent operation.

- 5. Pump Configuration

The FN608 is equipped with two independent fuel pumps, each corresponding to a separate fuel rail (left and right). Both pumps operate independently during testing — if one pump fails (e.g., the left pump), only the corresponding fuel rail is affected, while the other continues to function normally. This dual-pump system ensures greater reliability and uninterrupted testing. In contrast, the CT500 uses a single fuel pump, so a pump failure will stop the entire system until you replace the pump.

- 1. Testing Functions:

The CT450 adds the Pulse Injection Test compared to the CT400, while the CT500 further adds Wide Pulse Injection Test and Continuous Injection Test compared to the CT450, offering more advanced and versatile injector testing capabilities.

- 2. Cleaning & Heating Function:

The CT450 features ultrasonic cleaning with heating up to 50°C, whereas the CT400 and CT500 do not have a heating function, making CT450 more effective for thorough injector cleaning.

- 1. Supported Injector Types

CT200 only supports 12V standard fuel injectors, whereas CT400 supports both 12V standard and GDI (Gasoline Direct Injection) injectors, making it compatible with a wider range of injector types and vehicles.

- 2. Accessory Storage Design

CT200 does not have dedicated accessory storage, while CT400 features a drawer for injector adapters and other accessories, providing more convenient organization and storage.

- Both the CT150 and CT160 are designed for cleaning and testing fuel injectors of 4-cylinder gasoline engines.

The main difference is that the CT160 is equipped with an ultrasonic heating function, while the CT150 does not have this feature. - Compared with the CT150, the CT200 simply adds two more testing cylinders (6 in total), while the other functions remain the same.

- If you only need a tester for 12V gasoline fuel injectors, the CT160 is an excellent choice.

However, if you need to test GDI (Gasoline Direct Injection) high-pressure injectors, we recommend choosing CT400, CT450, CT500, FN606, or FN608 for better compatibility and performance.

AUTOOL Ultrasonic Fuel Injector Cleaner Quick Search

AUTOOL CT200 Fuel Injector Tester & Cleaner Machine Features:

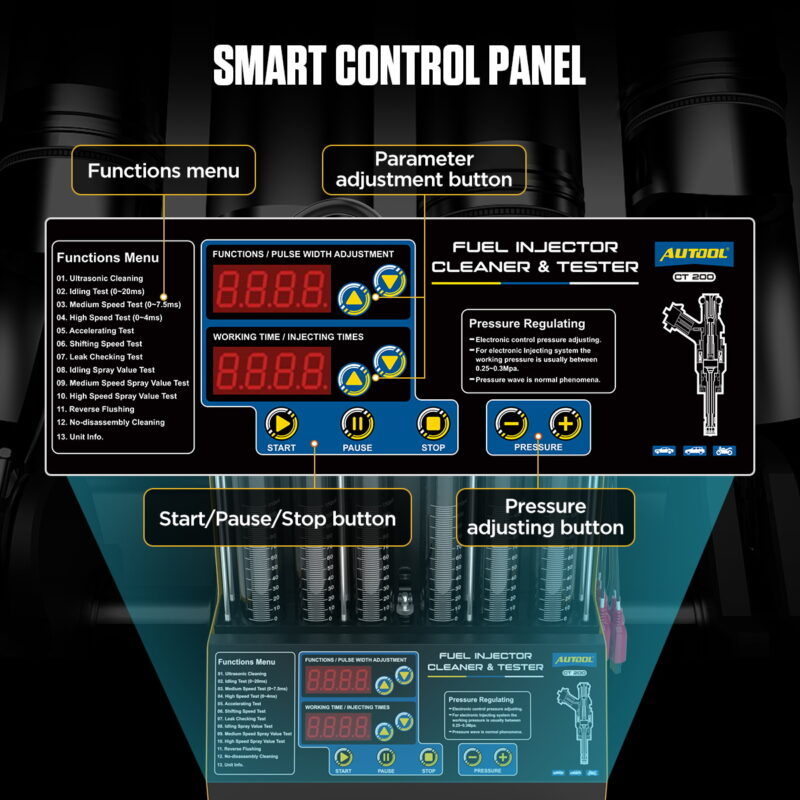

- Digital Display: With the help of microcomputer control and digital display, the equipment makes possible automatic cleaning, testing injectors, and real-time monitoring of the dynamic values.

- Adopting Humanization Design: Automatic fuel draining through preset programs for some test items. At the end of the test, pressing the button on the control panel, and draining the test fluid/cleaner, quickly restored the system pressure to its default value.

- Automatic Cleaning and Testing: Fuel pressure control through microcomputer offers stable pressure control and a large adjustable range, which is suitable for all EGI vehicles and can help to achieve automatic cleaning and testing of injectors.

- Reverse Flush: Uniformity/Sprayability test: To test the uniformity of injecting amount of each injector, and to monitor the spraying status of each injector with the help of backlight. This test is also for reverse flush.

- Three-Year Warranty, Lifetime Maintenance: For damage caused by non-human factors, AUTOOL promises to resend parts for free within 3 years. For any needs, you are warmly welcome to contact us and we will get back to you ASAP within 24 hours.

AUTOOL CT200 Fuel Injector Cleaner & Tester Functions:

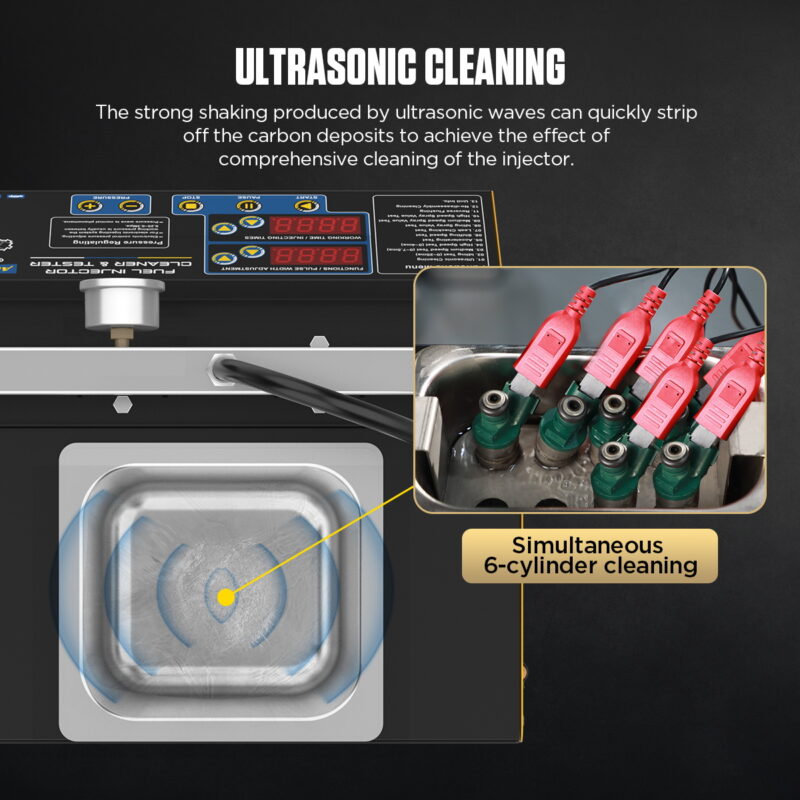

- Ultrasonic cleaning: It sends signals to the injectors through the pulse signal line, using the cleaning fluid with ultrasonic vibration so as to completely remove the carbon and impurities inside the injectors.

- Idle speed test (0-20ms): Simulate the engine idling speed and test the state of the fuel injector.

- Medium speed test (0-7.5ms): simulate the engine running at medium speed and test the state of the fuel injector.

- High-speed test (0-4ms): Simulate the high-speed performance of the engine and test the state of the fuel injector.

- Acceleration test: Simulate the acceleration state of the car and test the performance of the fuel injector.

- Shift speed test: Simulate the shifting state of the car and test the working performance of the fuel injector.

- Leakage test: Test the sealing condition of the fuel injector.

- Idle speed sprayability Test: Simulate the engine idling state and test the spraying performance of the fuel injector.

- Medium-speed sprayability test: Simulate the engine’s medium-speed state and test the spraying performance of the fuel injector.

- High-speed sprayability test: Simulate the high-speed state of the engine and test the spraying performance of the fuel injector.

- Reverse flush: Reverse flush is a way to clean the injectors with the test liquid flowing from the outlet to the inlet of the injector. Reverse flush may remove the dirt inside the injector or the injector Strainer (Only for the top fuel supply injector).

- No-disassembly cleaning: Direct cleaning without disassembling the injectors, this function is an additional function, that requires special adapters.

How To Use AUTOOL CT200 Injector Cleaning Machine?

- Clean injectors outside with gasoline or cleaning liquid before opening the machine

- Putting injectors in the ultrasonic bathtub after the outside of the injector is free of dirt.

- Turn on the ultrasonic system, pulsed allowing the ultrasonic energy to dislodge any particles that even build up inside the injectors.

- Fixed injectors on the main machine.

- Testing injectors for resistance, shorts, and current draw.

- Performing leak test, spray pattern, and flow rate testing on the flow bench.

- The injectors are now returned to the flow bench for retesting of all functions.

Operation Steps

- Ultrasonic Cleaning:

- Step 1: Pour in the detergent and place the fuel injector in the ultrasonic cleaner.

- Step 2: Connect the pulse signal wire & select the ultrasonic cleaning function to start working.

- Fuel Injector Testing:

- Step 1: Pour in the test liquid, install this injector to the fuel distributor, and fix it to the main unit by bolts.

- Step 2: Test if the fuel injector is leaking or blocked under different functions.

Packing List

Ultrasonic Fuel Injector Cleaner FAQs

AUTOOL CT series products can clean diesel injectors, but not test.

The test fluid assesses the fuel injector’s performance. It is a colorless, odorless, and non-corrosive liquid that simulates various injector working states. For best results, recommended to use a professional automotive injector test fluid. If the specified professional cleaning fluid is not available, then medical alcohol with more than 75% alcohol content can be used instead.

To clean deposits (such as carbon deposits) on fuel injectors, use a cleaning fluid that is highly corrosive and flammable. To ensure accurate and optimal testing results for fuel injectors, we recommend opting for a professional automotive injector ultrasonic cleaning fluid. If local options are unavailable, you may use 75%+ medical alcohol as a substitute, but its effectiveness may vary.

You don’t need any special settings. You simply select the feature number and set the test time via the control panel. The entire testing process is straightforward, efficient, and user-friendly.

Related blogs

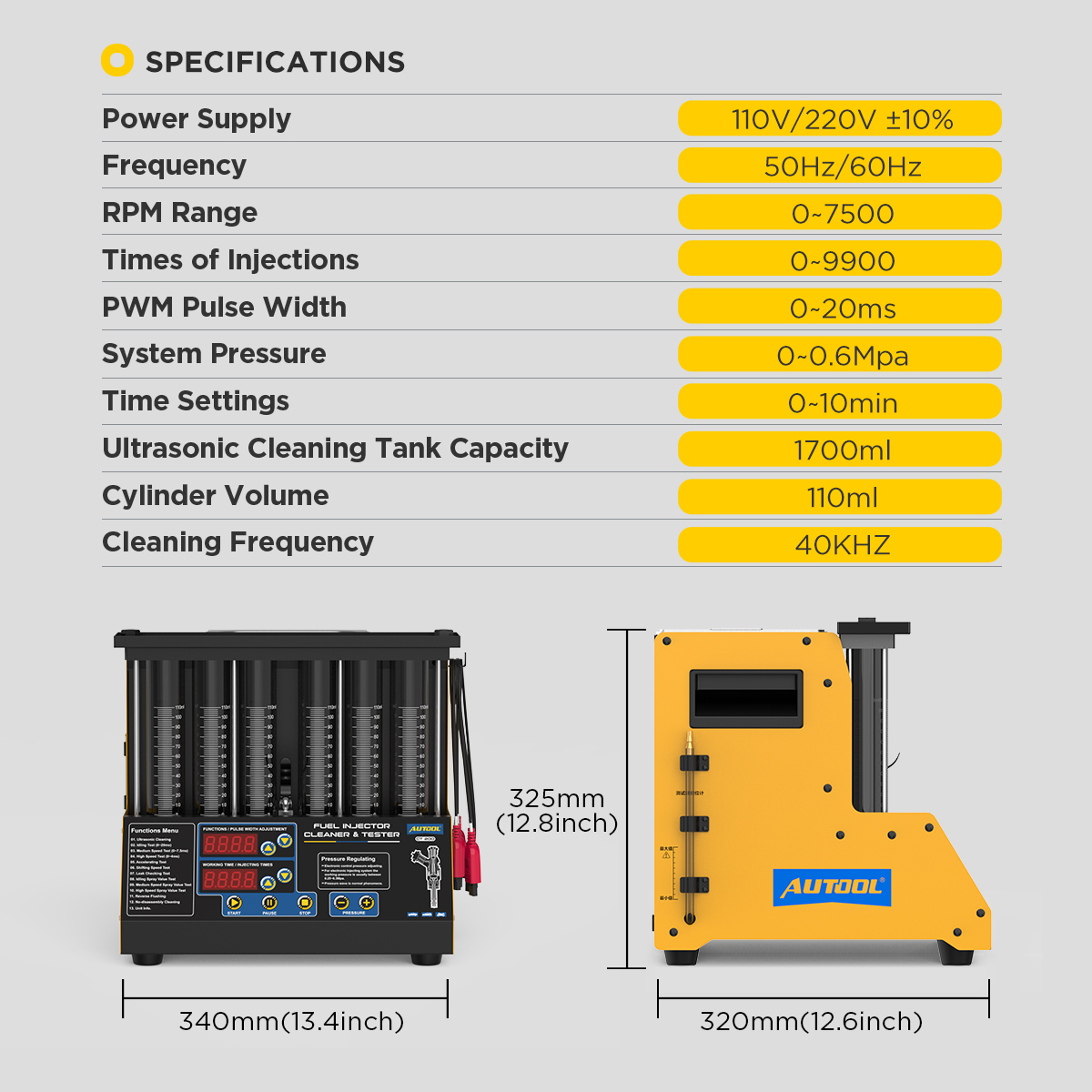

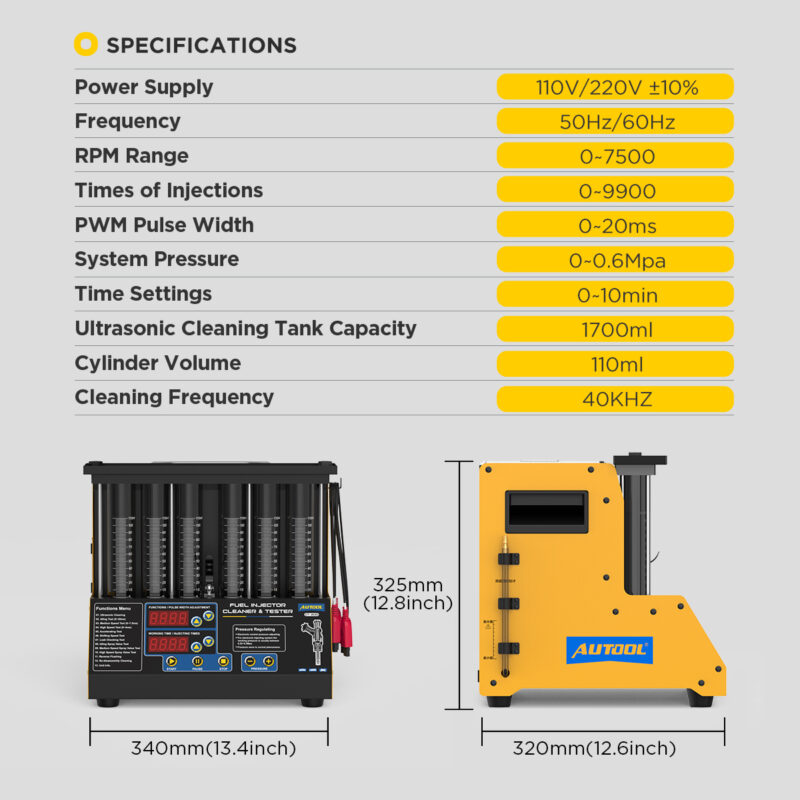

SPECIFICATIONS

- Brand Name: AUTOOL

- Origin: CN(Origin)

- Model: CT200

- Function: Gasoline Nozzle Cleaner

- Feature 1: Fuel Injectors Cleaner & Tester

- Feature 2: Ultrasonic Cleaning

- Feature 3: petrol machine, nozzle stand

- Feature 4: injectors tester

- Power: 110V & 220V