AUTOOL Blog, Purchase Guides

AUTOOL HTS709 Dry Ice Blaster for GDI Engine Carbon Cleaning

For car owners aiming to maintain peak vehicle performance, engine carbon buildup is a critical concern. Over time, carbon deposits accumulate on intake valves, intake runners, fuel injectors, and inside the combustion chamber—especially in GDI (Gasoline Direct Injection) engines—causing reduced power, higher fuel consumption, rough idling, and even engine knocking. Traditional carbon cleaning methods are often limited in effectiveness or require engine disassembly, which is time-consuming and labor-intensive.

With advances in automotive maintenance, dry ice blasting machines have emerged as a faster, safer, and more professional solution. The AUTOOL HTS709 dry ice blaster machine offers high cleaning efficiency, precise control, and cost-effectiveness, making it the preferred tool for many professional repair shops. This article will cover the causes of carbon buildup, compare different cleaning methods, highlight the advantages of dry ice cleaning, and explain why the HTS709 is revolutionizing GDI engine maintenance.

Understanding Engine Carbon Buildup

How Carbon Deposits Form

Carbon buildup primarily results from incomplete fuel combustion. When the air-fuel mixture does not burn completely, tiny carbon particles adhere to engine surfaces. Over thousands of miles, these deposits accumulate, forming hard, stubborn layers that are difficult to remove.

In GDI engines, fuel is injected directly into the combustion chamber rather than the intake manifold. While this design improves fuel efficiency and performance, it eliminates the natural “washing” effect that fuel has on intake valves. Additionally, oil vapors from the PCV system and exhaust gases from the EGR system tend to settle on the valves, accelerating carbon buildup.

Effects of Carbon Buildup

Excessive carbon deposits can severely impact engine performance:

- Reduced airflow: Deposits narrow the intake passages, affecting the air-fuel mixture.

- Increased fuel consumption: The engine burns more fuel to maintain performance.

- Power loss: Restricted airflow and incomplete combustion reduce horsepower.

- Engine knocking: Hotspots from carbon deposits may cause pre-ignition.

- Check Engine Light: Sensors detect misfires or airflow irregularities caused by carbon deposits.

Traditional Carbon Cleaning Methods and Their Limitations

For decades, mechanics have relied on two primary approaches to remove carbon:

1. Chemical Cleaners / Fuel Additives

These involve adding cleaning agents to the fuel or directly into the intake system. While effective for light carbon buildup, they struggle with the stubborn deposits common in GDI engines. Harsh chemicals can also damage gaskets, seals, and other precision engine components.

2. Manual Cleaning / Walnut Sand Blasting

This method requires disassembling parts of the engine to access the intake valves, then blasting the surface with crushed walnut shells. Although effective and relatively affordable, it has limitations:

- Requires engine disassembly, increasing labor costs and downtime.

- Cannot clean the engine bay, chassis, or other external components.

Both approaches involve long vehicle downtime and high labor costs, prompting many shops to adopt more advanced solutions.

The Rise of Dry Ice Engine Cleaning

Dry ice blasting is a non-abrasive, eco-friendly, and efficient cleaning method. Solid CO₂ pellets are propelled at high speed using compressed air, and upon impact, they sublimate instantly, creating a micro-explosion that removes carbon deposits without damaging the underlying surfaces.

Advantages of Dry Ice Cleaning

- Non-abrasive: Safe on aluminum cylinder heads, valves, and other precision parts.

- Residue-free: Dry ice completely sublimates, leaving no blasting media.

- No disassembly required: Can clean through spark plug holes or other access points.

- Fast turnaround: Most engines can be cleaned within 1–2 hours.

- Environmentally safe: No chemicals or secondary waste produced.

Compared to chemical cleaning or walnut shell blasting, dry ice blasting machines for cars offer faster, safer, and more cost-effective GDI engine maintenance.

Why AUTOOL HTS709 Dry Ice Blasting Services Stands Out

The AUTOOL HTS709 dry ice blaster machine is specifically designed for automotive maintenance, making it ideal for GDI engine carbon cleaning.

Precision Nozzle Design

- Thin, long nozzle reaches spark plug holes to clean valves and piston tops without disassembly.

- Flat nozzle option for rapid cleaning of engine bays or exterior components.

- Adjustable spray angles ensure thorough cleaning without damaging metal surfaces.

Adjustable Blasting Pressure

- Tailor pressure for different engine types and carbon severity.

- Gentle cleaning for new engines; stronger impact for older, heavily carbonized engines.

Compact and Cost-Effective

- Lightweight and portable, perfect for repair shops, detailing centers, or mobile services.

- Industrial-grade blasting power with lower investment than large-scale machines.

Proven Performance

- Widely used in Europe, North America, and the Middle East by professional mechanics and car detailers.

- Provides a high-efficiency, safe, and eco-friendly solution for carbon removal.

Cost and Efficiency Comparison

As can be seen from the table, dry ice blaster cleaning machine have significant advantages in terms of time, risk, and cleaning effect. Not only is the cleaning speed fast, but it also does not damage engine parts, and there is no need to treat secondary waste, making it environmentally friendly and efficient.

|

Method |

Average Time |

Cost (USD) |

Damage Risk |

Residue |

|

Chemical Cleaners |

2–4 hours |

150–300 |

Low to medium |

Chemical waste |

|

Walnut Shell Blasting |

6–8 hours |

500–800 |

Medium |

Shell particles |

|

Dry Ice Blasting |

1–2 hours |

300–500 |

Very low |

None |

Tips for Using Dry Ice Blasting Machines

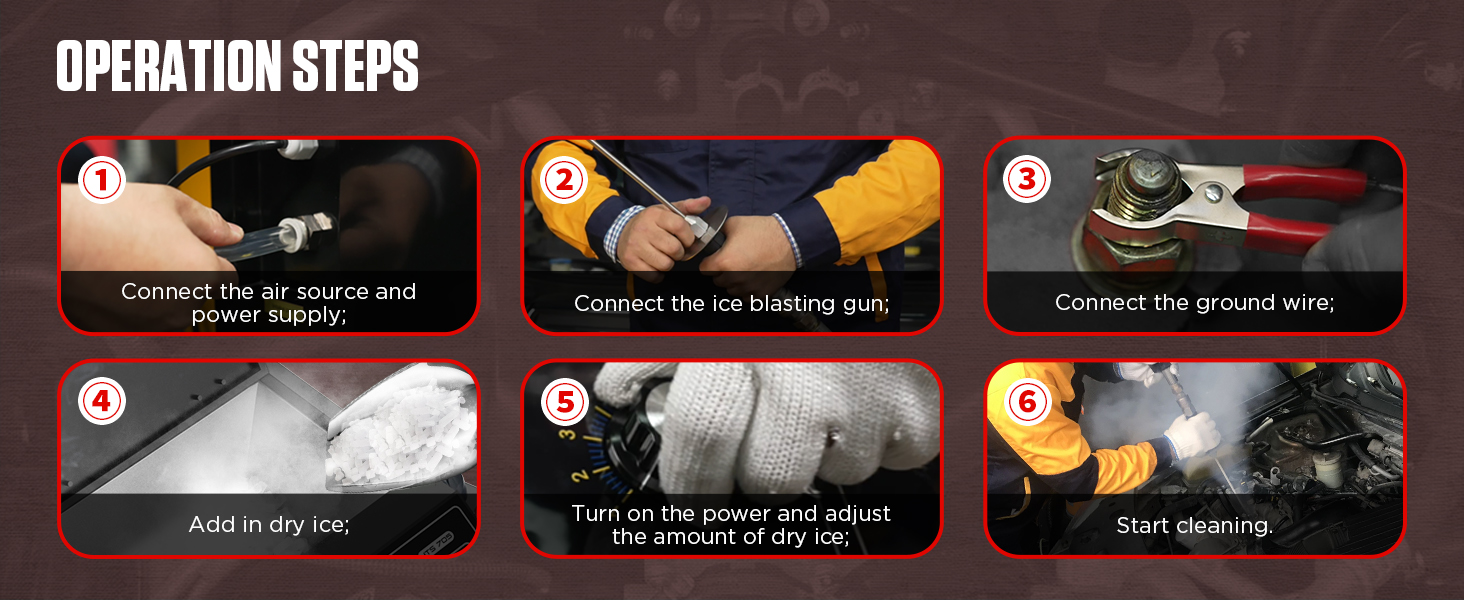

- Use a compressor ≥7.5 kW with a 300L tank for stable airflow.

- Dry ice pellet size: 3–5 mm is optimal; crush larger blocks if necessary.

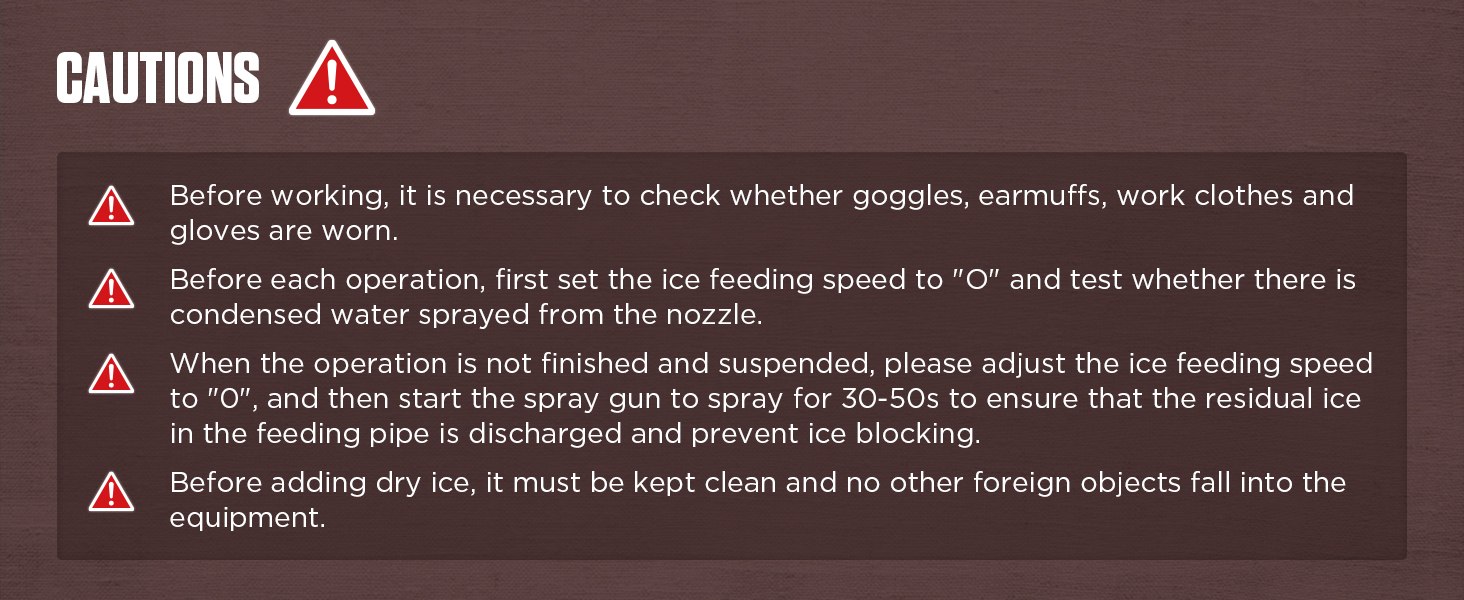

- Wear protective gloves and goggles to prevent frostbite from dry ice contact.

Beyond Engine Carbon Cleaning: Other Automotive Applications

The AUTOOL HTS709 is versatile and can handle multiple automotive cleaning tasks:

- Engine bay cleaning without damaging electronics or wiring.

- Chassis and suspension cleaning to remove mud, salt, and road grime.

- Precision cleaning of wheel arches and hard-to-reach components.

- Restoration of classic or high-end car parts, preserving original surfaces.

This versatility makes the HTS709 a multi-functional tool for professional repair shops, car detailers, and mobile services.

Conclusion: Smarter GDI Engine Maintenance

The AUTOOL HTS709 dry ice blaster machine offers a revolutionary solution for engine carbon cleaning—powerful, precise, efficient, and eco-friendly. It restores engine performance without disassembly or corrosive chemicals, reducing downtime and repair costs.

With multi-functional applications, the HTS709 is not only ideal for GDI engine cleaning, but also for engine bay, chassis, suspension, and classic car maintenance, making it a must-have tool for professional repair shops and automotive detailers worldwide.

👉Want to learn more? Contact us to enjoy a 10% discount for new customers and 3-year warranty!

-

WhatsApp: +86 189 2647 7404

-

Email: shop@autooltech.com