AUTOOL Walnut Blasting Machine for Intake Valve Carbon Cleaning

$335.00 – $2399.00

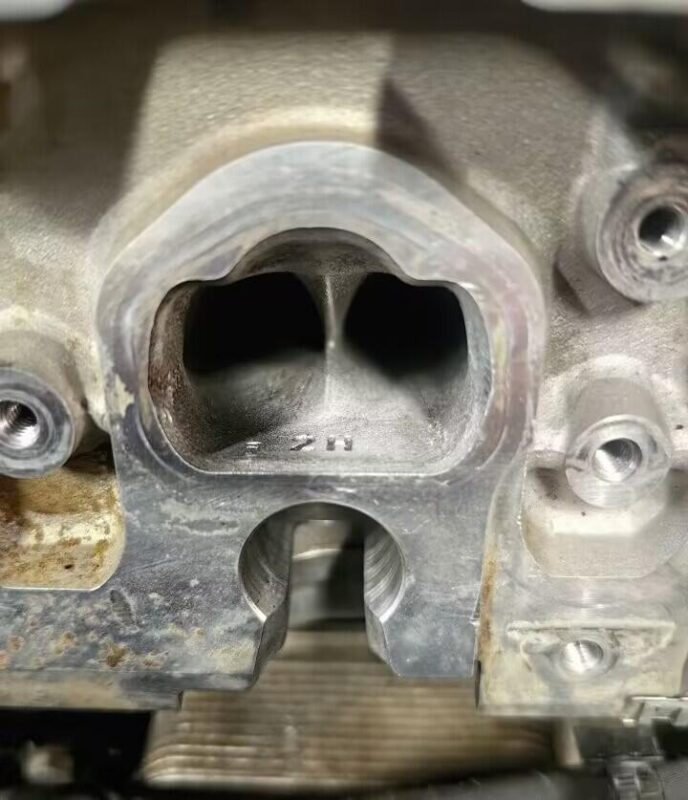

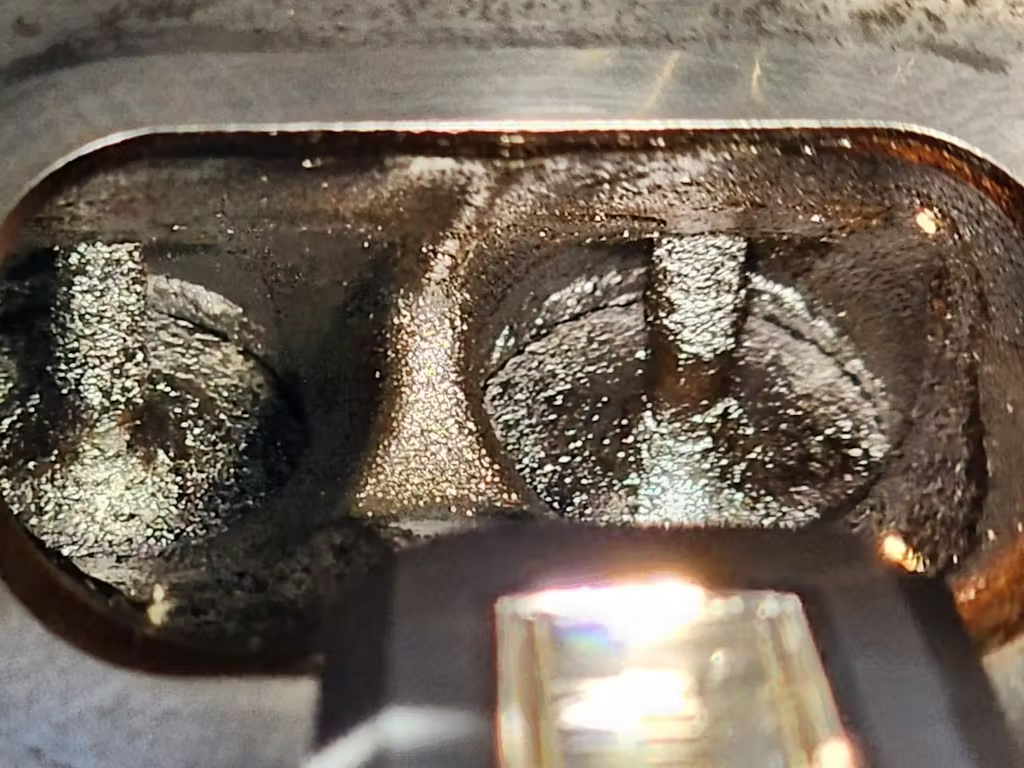

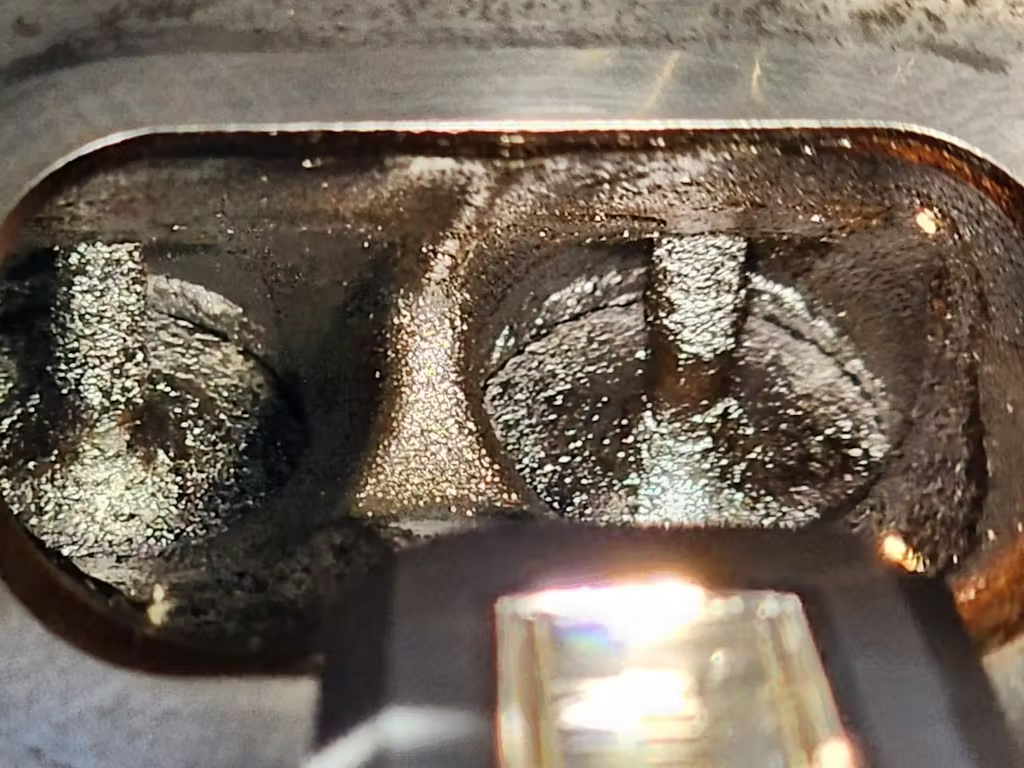

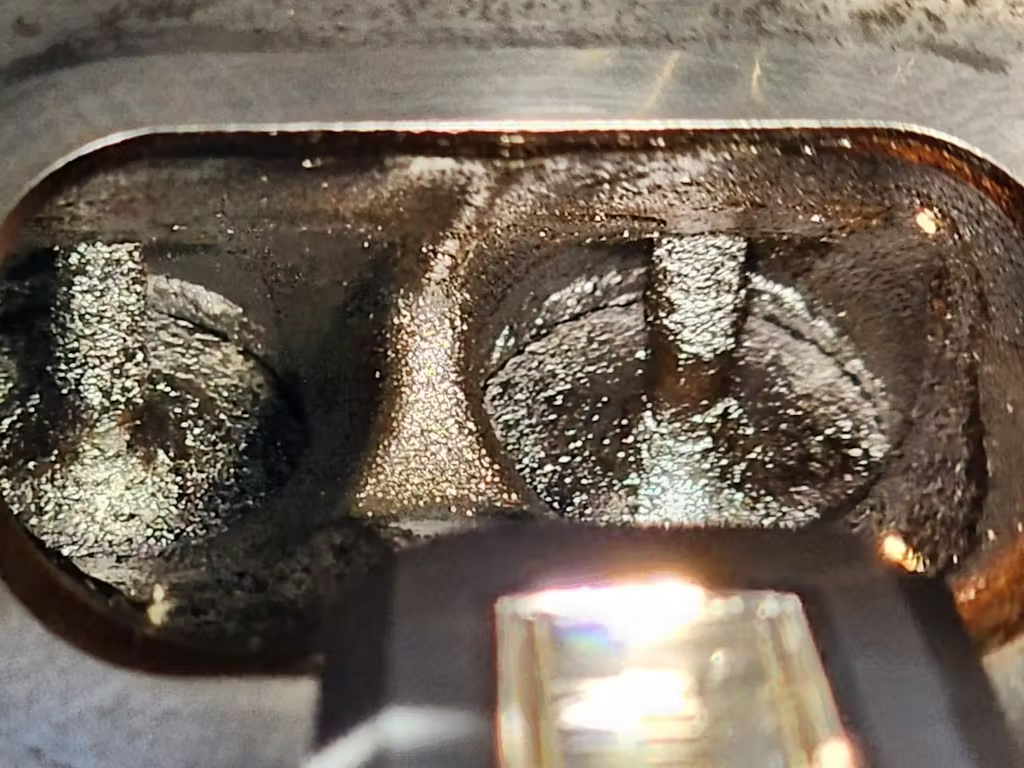

- Intake Manifold, Intake and Exhaust Valve Cleaning: Efficiently removes carbon deposits from the intake manifold and valves without damaging the engine.

- Combustion Chamber Cleaning ( Only HTS728 can): Designed for HTS728, removes carbon deposits from the combustion chamber.

For wholesale prices and more discounts click here.

Please select the correct warehouse before payment. Such as EU users choosing Germany stock will enjoy free shipping and no customs duties (except Serbia and Cyprus).

The AUTOOL walnut blasting machine is a professional-grade tool designed for cleaning stubborn carbon deposits in the intake manifold, intake/exhaust valves, and combustion chamber. Unlike chemical cleaners, walnut blasting uses eco-friendly walnut shell media, ensuring thorough cleaning without damaging sensitive engine components.

Working Principle

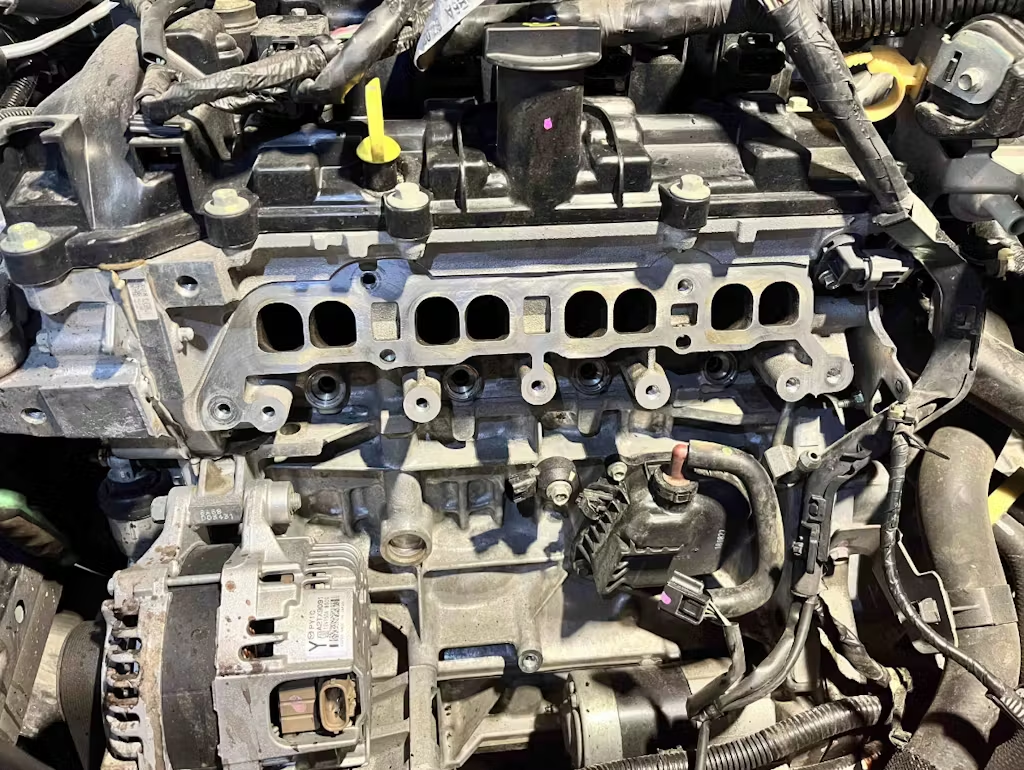

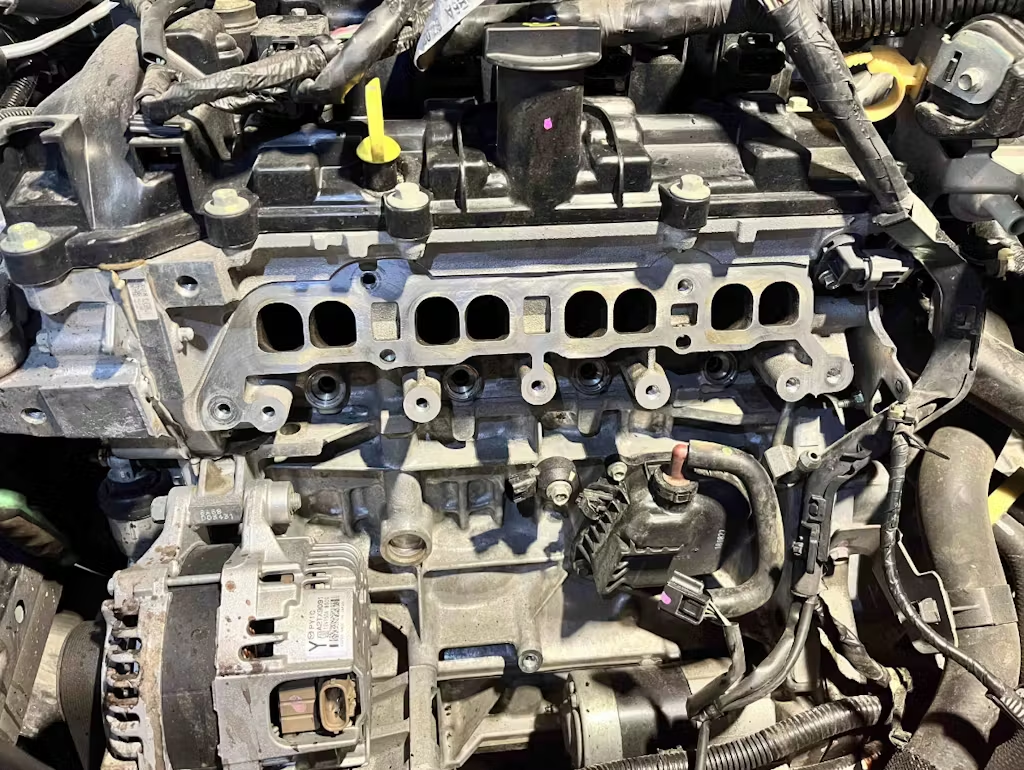

AUTOOL walnut shell sand blaster uses compressed air to spray walnut shells at high speed into the engine intake manifold. The walnut particles continuously tumble and impact inside the manifold, effectively removing carbon deposits from the intake valves and cylinder walls. Afterwards, the device uses a special connector and suction pipe to recover the walnut shells together with the loosened carbon deposits into the storage tank, achieving an efficient, safe, and residue-free cleaning process.

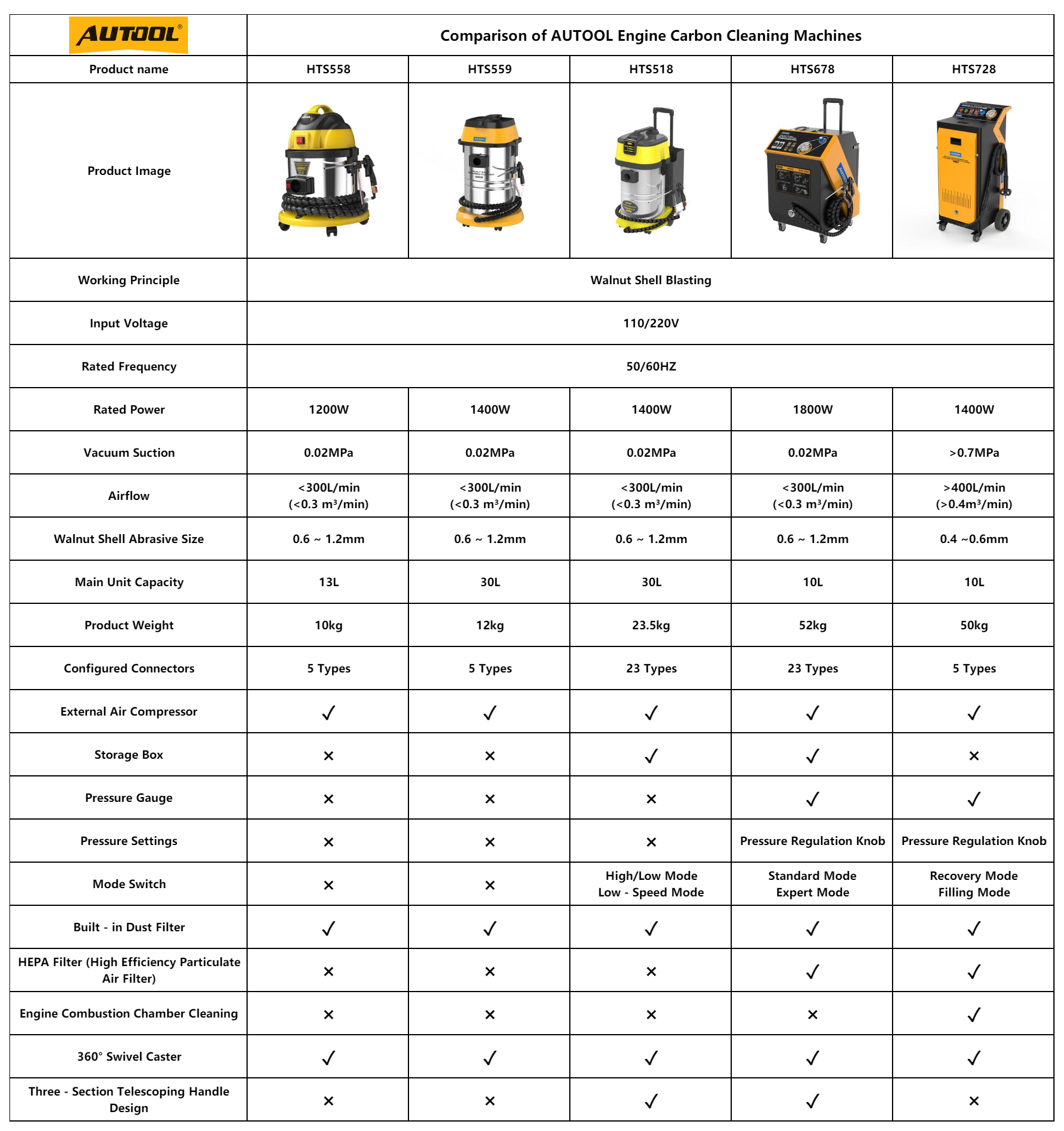

Walnut Blasting Machine Comparison: Which One Fits You Best?

How to Choose HTS Series Walnut Blaster?

Only the AUTOOL HTS728 walnut blaster supports cleaning carbon deposits in the combustion chamber. Other models do not support this function.

If you require high-efficiency particle filtration, we recommend the AUTOOL HTS728 or HTS678 walnut blaster.

HTS558, HTS518, and HTS559 do not support pressure adjustment and do not have a pressure gauge. We recommend choosing HTS678 or HTS728, which allow you to freely adjust the output pressure according to your cleaning needs, from gentle cleaning to high-power sandblasting.

Air pressure up to 0.7mpa, 6bar or more air pressure.

We recommend using an air compressor equipped with a dryer filter to effectively prevent moisture buildup, which can cause walnut shell media to clump and result in poor blasting performance.

HTS558, HTS518, HTS519, and HTS678 can use walnut shells with a particle size of 0.6–1.2 mm, while HTS728 uses finer walnut shells with a particle size of 0.4–0.6 mm, offering smaller, more precise abrasive particles for delicate cleaning.

The walnut blaster requires 2–3 kg of walnut shell media to operate. The walnut media can be recycled and reused approximately 5–10 times.

⚠️ Must Read Before Use

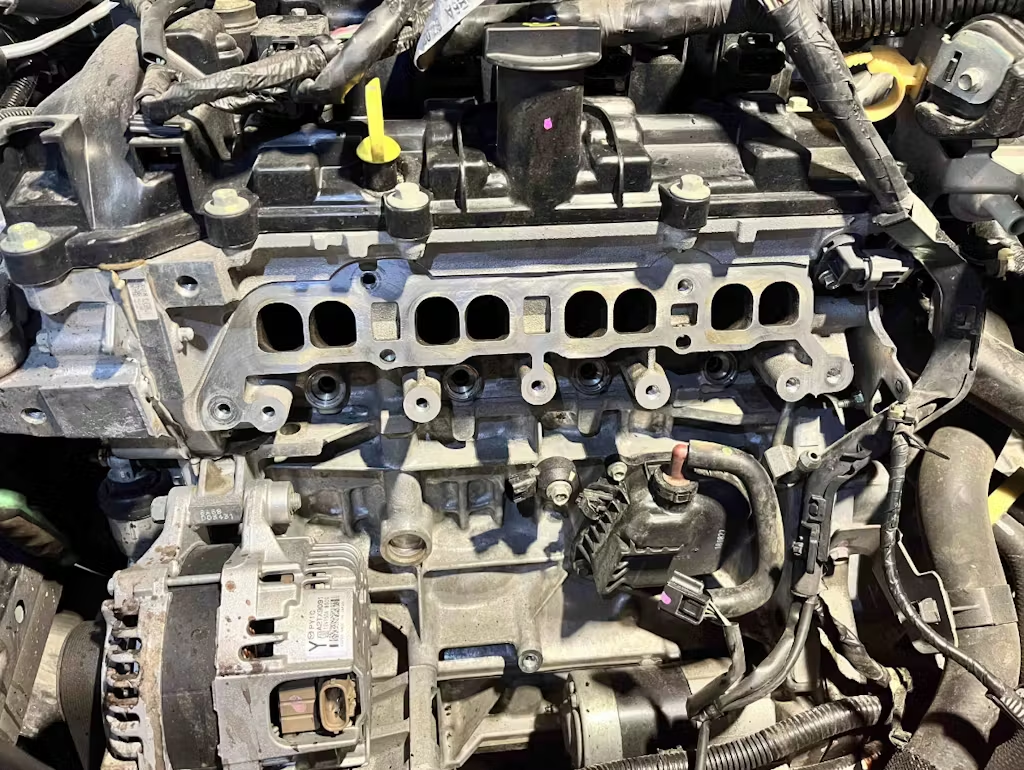

- High-precision engine systems are very sensitive to foreign particles in the intake manifold, such as the BMW Valvetronic system. Therefore, before cleaning carbon deposits in the intake manifold, the engine should be turned off, and the crankshaft rotated to close the intake valves. The AUTOOL walnut sandblaster cleans one intake port at a time, so a six-cylinder engine requires cleaning each of the six ports individually.

- The package does not include an air compressor, which must be purchased separately.

- Any walnut shell residue left in the intake manifold will turn to ash under high temperatures once the engine starts, so there is no need for concern.

🔔 Warm Tips

- The walnut sand blasting machine is not suitable for cleaning the car chassis. If you need to clean the chassis, we recommend using a dry ice cleaning machine.

AUTOOL Walnut Shell Blaster Machine Functions

- Intake Manifold Cleaning: The sandblasting method efficiently removes carbon deposits from the engine’s intake manifold, ensuring a thorough and effective cleaning.

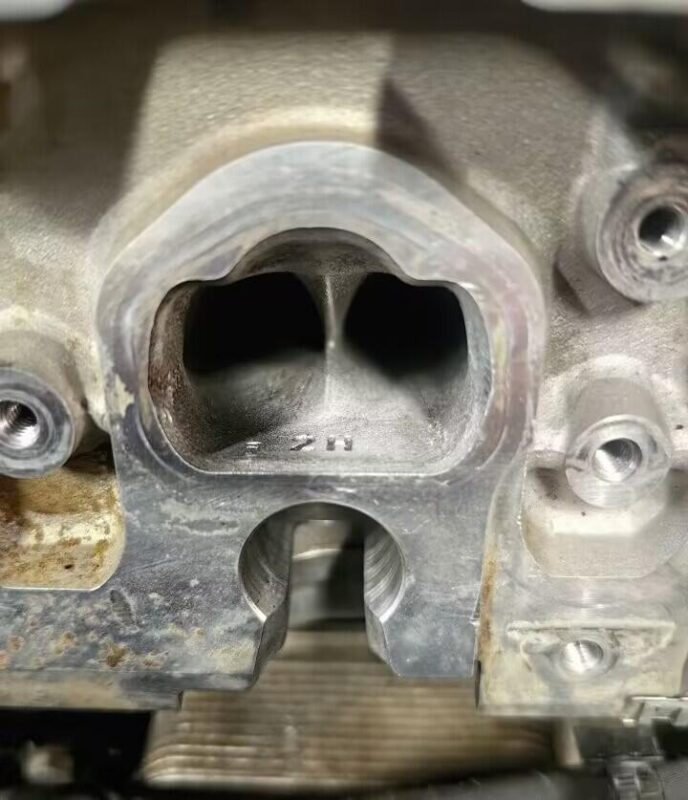

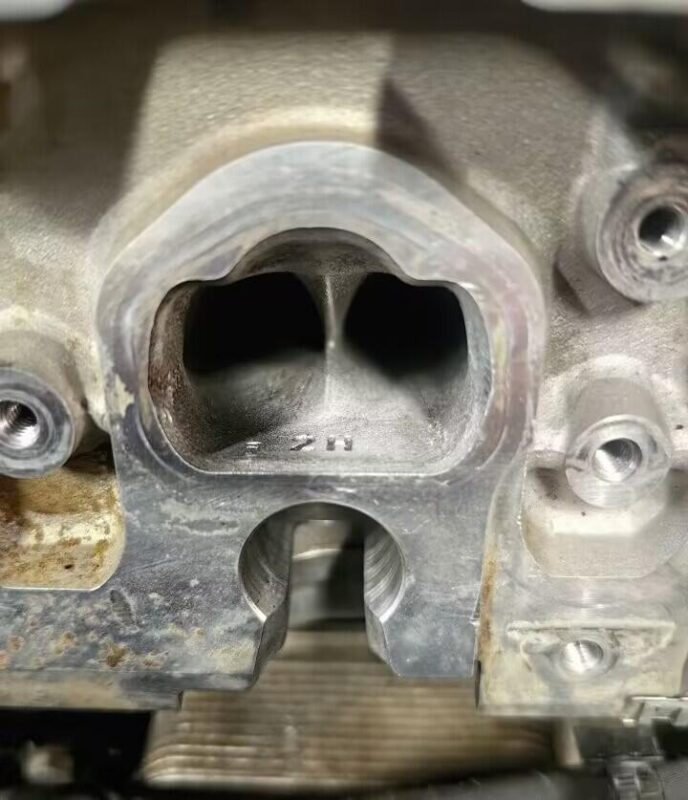

- Intake/Exhaust Valve Cleaning: Following the sandblasting sequence, this process thoroughly cleans carbon deposits from the valves without causing any damage to the engine.

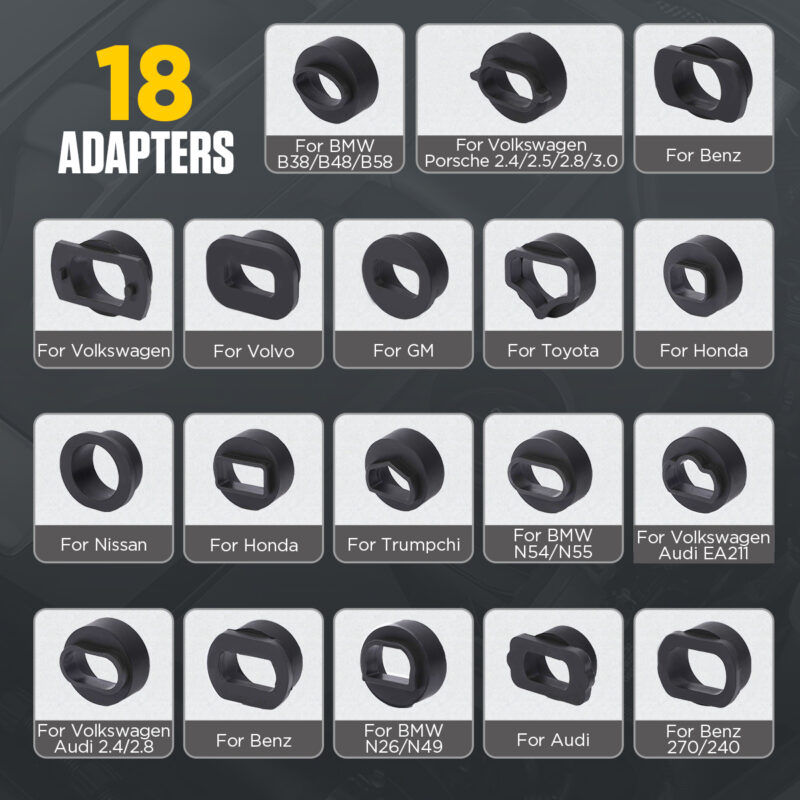

- Multiple Adapters: Comes with adapters, compatible with a wide range of vehicle models.

- External Air Source Design: Powered by a high-performance motor using an external air source, the machine delivers continuous power. This increases the impact force of the walnut shell abrasive, ensuring complete removal of carbon deposits from engine pipes.

- Built-in Dust Filter: Spraying and recovery are performed simultaneously. The filter separates walnut shell abrasive from carbon deposits, allowing the abrasive to be reused while preventing residual particles from damaging the exhaust system at high temperatures.

- Integrated Design: The walnut shell abrasive is automatically recycled within the machine, eliminating the need for manual recovery and saving time and effort.

- User-Friendly: Equipped with 360° swivel casters for easy mobility and operation.

- 3-Year Warranty: For damage caused by non-human factors, we provide free replacement parts within 3 years.

AUTOOL Walnut Shell Sand Blaster Quick Search

FAQs

- Please check if there is walnut sand abrasive in the abrasive outlet tube of the blasting nozzle.

- You can block the blasting nozzle with a cloth and spray several times to use the air pressure to backflush and clear the blasting nozzle tube. Then remove the cloth and spray into a waste collection bucket to see if the walnut sand abrasive is being discharged normally again.

- During normal use, try pressing the spray button intermittently. This will provide stronger cleaning power and better cleaning results.

- If the walnut sand abrasive is clogged at the blasting nozzle, please disassemble the blasting nozzle and manually clear the blockage.

- If the issue persists and it remains stuck, we will send you a new blasting nozzle to completely resolve the problem.

- The blasting nozzle’s switch part needs to be replaced. I will send you a new switch part. After replacement, the blasting nozzle air leakage issue will be resolved.

- Please open the machine casing and use a multimeter to measure the input and output voltage of the wires connected to the switch button. This will help determine whether the issue is with the switch button not functioning or with a motor fault.

- We sincerely apologize for the inconvenience. It seems that the damage to the wheels was caused by a logistics issue. Please provide photos of the damaged wheels so we can assess how many wheels are affected. We will send you new wheels for replacement

If You Want to Get More Discounts, Please Contact Us

- WhatsApp: +86 18926477404

- Email : shop@autooltech.com

Delivery

3 reviews for AUTOOL Walnut Blasting Machine for Intake Valve Carbon Cleaning

| 5 star | 100 | 100% |

| 4 star | 0% | |

| 3 star | 0% | |

| 2 star | 0% | |

| 1 star | 0% |

Customer Images

Elian Home

This walnut sand blasting cleaning machine has an excellent cleaning effect, especially in removing carbon deposits from the intake manifold and intake and exhaust valves. Equipped with a variety of adapters, it has strong compatibility and is suitable for a variety of vehicle models. The external air source design brings continuous and strong power, effectively improving the impact of the walnut sand and cleaning more thoroughly. The built-in dust removal and filtration system supports simultaneous injection and recovery, which not only avoids damage to the engine by residues, but also recycles the cleaning medium to save costs. The overall integrated design saves time and effort, is simple to operate, and the universal wheels at the bottom are easy to move, providing a very good user experience. The three-year warranty also gives people great peace of mind, and is highly recommended!

Elian Home

This walnut sand blasting cleaning machine has an excellent cleaning effect, especially in removing carbon deposits from the intake manifold and intake and exhaust valves. Equipped with a variety of adapters, it has strong compatibility and is suitable for a variety of vehicle models. The external air source design brings continuous and strong power, effectively improving the impact of the walnut sand and cleaning more thoroughly. The built-in dust removal and filtration system supports simultaneous injection and recovery, which not only avoids damage to the engine by residues, but also recycles the cleaning medium to save costs. The overall integrated design saves time and effort, is simple to operate, and the universal wheels at the bottom are easy to move, providing a very good user experience. The three-year warranty also gives people great peace of mind, and is highly recommended!

Muhammad Maroof

The HTS728 walnut sandblasting machine has excellent cleaning results. Besides cleaning intake valve carbon deposits, it can also be used to remove combustion chamber carbon deposits. This is a unique machine on the market. By the way, if you contact customer service before purchasing, you can receive an additional 2kg of walnut sand as a free gift.

Muhammad Maroof

The HTS728 walnut sandblasting machine has excellent cleaning results. Besides cleaning intake valve carbon deposits, it can also be used to remove combustion chamber carbon deposits. This is a unique machine on the market. By the way, if you contact customer service before purchasing, you can receive an additional 2kg of walnut sand as a free gift.

Sarah Klassen

It only took 15 minutes to complete the cleaning of the intake valve. However, HTS678 does not support cleaning the carbon deposits in the combustion chamber, only HTS728 supports

Sarah Klassen

It only took 15 minutes to complete the cleaning of the intake valve. However, HTS678 does not support cleaning the carbon deposits in the combustion chamber, only HTS728 supports

Sorry, no reviews match your current selections

AUTOOL Walnut Blasting Machine for Intake Valve Carbon Cleaning

AUTOOL Walnut Blasting Machine for Intake Valve Carbon Cleaning

This walnut sand blasting cleaning machine has an excellent cleaning effect, especially in removing carbon deposits from the intake manifold and intake and exhaust valves. Equipped with a variety of adapters, it has strong compatibility and is suitable for a variety of vehicle models. The external air source design brings continuous and strong power, effectively improving the impact of the walnut sand and cleaning more thoroughly. The built-in dust removal and filtration system supports simultaneous injection and recovery, which not only avoids damage to the engine by residues, but also recycles the cleaning medium to save costs. The overall integrated design saves time and effort, is simple to operate, and the universal wheels at the bottom are easy to move, providing a very good user experience. The three-year warranty also gives people great peace of mind, and is highly recommended!

The HTS728 walnut sandblasting machine has excellent cleaning results. Besides cleaning intake valve carbon deposits, it can also be used to remove combustion chamber carbon deposits. This is a unique machine on the market. By the way, if you contact customer service before purchasing, you can receive an additional 2kg of walnut sand as a free gift.

It only took 15 minutes to complete the cleaning of the intake valve. However, HTS678 does not support cleaning the carbon deposits in the combustion chamber, only HTS728 supports