Uncategorized

Cleaning Engine Carbon -Dry Ice Blasting and Walnut Blasting

Cleaning engine carbon deposits: Is it necessary?

The engine, as the “heart” of the car, can have its performance gradually affected by severe carbon buildup. Over time, some residues from incomplete combustion inevitably accumulate inside the engine, forming what we call “carbon deposits.” So, which cleaning method should we choose? This article will help you understand the importance of engine carbon cleaning and introduce two common cleaning methods: Ice Blasting Machine(Dry Ice Blasting) and Walnut Blasting Cleaning.

What is engine carbon deposits?

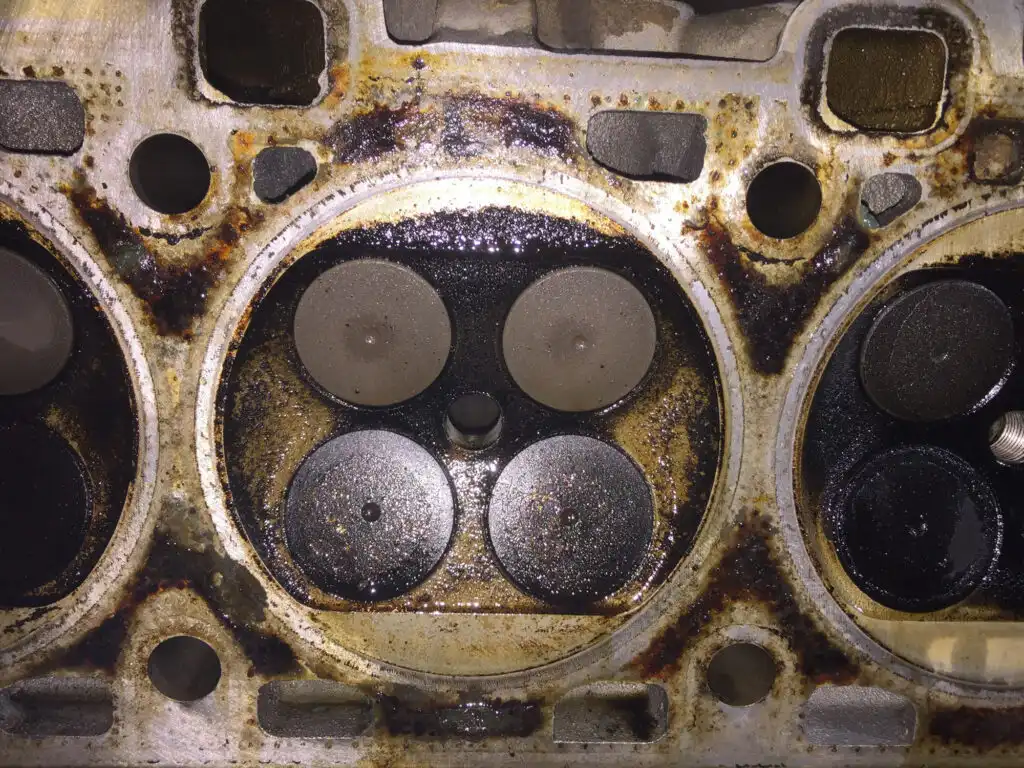

Engine carbon is the engine in the process of operation. Unsaturated hydrocarbons and gums in the oil and fuel are residues produced by incomplete combustion at high temperatures. These residues can not be discharged in time with the exhaust gas. Instead, it accumulates in various parts of the system, forming black carbide.

The two main causes of carbon deposits are insufficient combustion within the engine and poor-quality fuel. Carbon deposits can be categorized into three types: valve carbon deposits, combustion chamber carbon deposits, and intake manifold carbon deposits.

What are the symptoms of carbon buildup?

The formation of engine carbon buildup is a gradual process, and over time, it can affect vehicle performance. Here are some common signs that need cleaning engine carbon buildup:

- Drivability issues, engine not running smoothly

- Engine vibration or shaking

- Car jerking or surging at stops

- Check engine light may be on

- Cold start misfires

If your vehicle shows one or more of these symptoms, it is likely that carbon buildup is severe inside the engine, and it is advisable to clean the carbon deposits promptly to restore normal engine function.

Two Methods For Cleaning Engine Carbon Deposits

-

Dry Ice Blasting

Dry ice blasting is a new cold spray technology that uses high-pressure air from an air compressor to project dry ice onto carbon deposits in the engine. The accelerated dry ice particles impact the carbon, creating cracks, while the low temperature of the dry ice freezes and embrittles the carbon, reducing its adhesion. This ice blasting machine can quickly detaches dirt and oil from the surface without damaging the engine’s metal surfaces or affecting its seals.

Typically use about 15 kg of dry ice to effectively clean both valve and combustion chamber carbon deposits without disassembling the engine. However, dry ice is a consumable, and purchasing it regularly can incur significant costs over time.

-

Walnut Sand Cleaning

Walnut sand cleaning technology utilizes the principle of sandblasting to remove engine carbon deposits. When the walnut sand cleaning machine is connected to an air compressor, high-pressure air pushes walnut sand through the blasting nozzle into the engine’s intake manifold. The high-speed flow of walnut sand particles rolls and collides within the enclosed intake manifold, effectively scrubbing away carbon deposits from the intake valves and the walls of the intake manifold. The removed carbon and walnut sand are then vacuumed out by a suction device.

Walnut sand is an organic, natural polishing material rather than a chemical substance, so using it as an abrasive does not damage the surface of the workpiece. This method is gentle on the engine while providing noticeable cleaning results. Additionally, walnut sand can be reused and is relatively inexpensive. However, walnut sand cleaning has its limitations: it can only remove carbon deposits from the intake valves and cannot address carbon buildup within the combustion chamber, making it less comprehensive.

How to Prevent Engine Carbon Buildup?

Carbon buildup can’t be completely avoided, but it can be controlled.

2. Avoid long periods of idling:

Frequent idling reduces the airflow into the engine, weakening its ability to flush out carbon deposits and promoting buildup.

3. Regular maintenance:

Keep the fuel and air systems clean by performing maintenance every 4,000 to 8,000 km (depending on vehicle use and condition).

Carbon buildup in the engine is not a serious problem as long as regular maintenance is done and proper cleaning methods are used. For everyday vehicles, fuel additives and periodic manual cleaning are good ways to prevent and maintain engine health. For more severe carbon buildup, walnut blasting and dry ice cleaning are effective solutions. Each method has its advantages, so owners should choose based on their vehicle’s condition and budget to keep the engine running in top shape.

If you want to know more, you can contact the online customer service!

Related Blog

- AUTOOL Dry Ice Blaster Machine-The Best Solution

- Why and how to use a HTS558 Engine Cleaner?

- Engine Decarbonization-Why and Solutions