Purchase Guides, Uncategorized

Application of dry ice cleaning technology in the automotive industry

Dry ice blasting technology originated in the United States aerospace industry in the 1940s, where it was first used to clean aircraft components. It is a cleaning and surface-treatment method that uses solid carbon dioxide (dry ice) particles to remove contaminants without damaging the underlying material.

Today, both automotive repair shops and vehicle manufacturers can achieve significant operational improvements by adopting dry ice cleaning technology. AUTOOL dry ice cleaning machines are not only ideal for maintaining injection molds and cleaning welding fixtures, but also enable faster and more efficient cleaning of die-casting tooling and electrical distribution equipment—delivering superior cleaning results overall.

Dry ice cleaning significantly reduces equipment downtime, improves component quality, and eliminates the safety risks associated with manual cleaning and chemical solvents, making it a cleaner, safer, and more efficient solution for modern automotive operations.

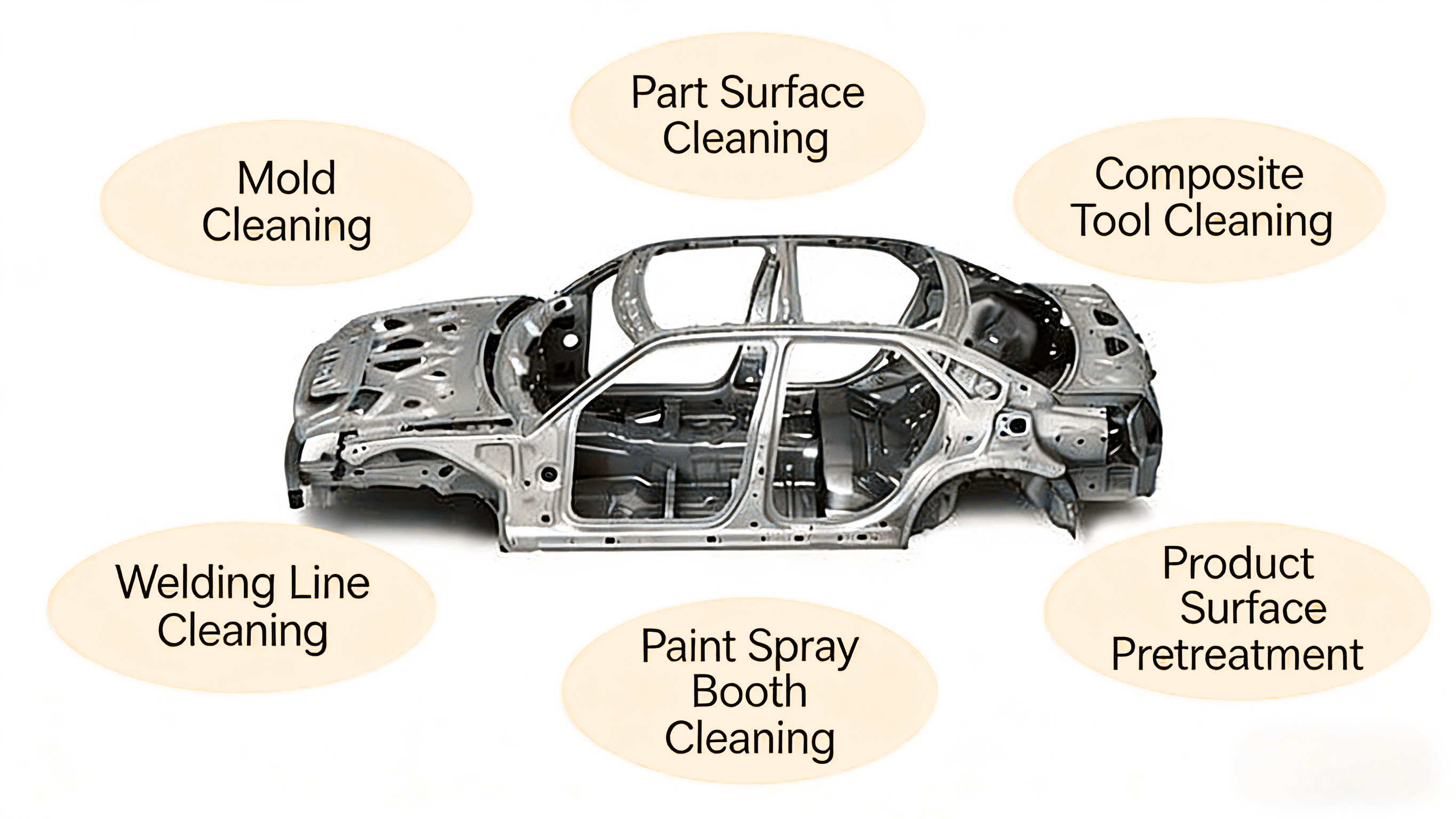

Applications of Dry Ice Cleaning Machines in the Automotive Industry

Application in Automotive Manufacturing:

Application in the Automotive Tire Industry:

Application in the Automotive Interior Industry:

Conclusion

Originating from the aerospace industry, dry ice cleaning is a highly efficient solution for the automotive sector. Its advantages—efficiency, environmental friendliness, non-destructive performance, and safety—make it suitable for manufacturing, tire production, vehicle maintenance, and interior cleaning. By reducing downtime, eliminating chemical pollution, and avoiding secondary waste, it supports stricter environmental regulations and the industry’s move toward sustainability.

As the automotive industry continues to demand higher cleaning efficiency, stricter environmental standards, and greater process precision, dry ice cleaning technology is set to play a pivotal role. AUTOOL dry ice cleaning machines, with their innovative technology and practical design, offer users reliable, economical, and intelligent solutions. They not only help businesses improve production efficiency and product quality but also inject fresh momentum into the industry’s green transformation. When making a purchasing decision, it is recommended that users prioritize mature, well‑serviced, and cost‑effective brands based on their actual needs and equipment performance to maximize cleaning benefits and return on investment.

👉 Get 10% off for new customers plus a 3‑year warranty on all Tire Balancer Machines for cars!

📩 Contact Us Today:

• WhatsApp: +86 189 2647 7404

• Email: shop@autooltech.com