AUTOOL Blog, Purchase Guides

How to Choose the Right Walnut Blasting Machine for You

Define Your Needs: Adaptability is Key

Before choosing a walnut blasting kit, ask yourself two questions: “What will I clean?” and “How often will I clean?” These questions directly affect the device’s core parameters and help you avoid overpaying for an overly powerful model or buying a model that’s too weak and prone to damage.

Clarify What You Need to Clean

- Small Parts Cleaning: If you only need to clean spark plugs, throttle bodies, intake valves, and other small components, opt for a compact, portable walnut blasting tool. Focus on fine control of the grinding process to avoid damaging delicate parts with large walnut media.

- Mainstream Cleaning Tasks: For cleaning car/truck engine cylinders, intake manifolds, and combustion chambers (the most common needs), go for a medium-sized standard model. The key is to ensure stable pressure and high walnut media circulation efficiency, ensuring a thorough clean without damaging the engine.

Frequency of Use

- Low-Frequency Use: For personal shops, part-time repair businesses, or occasional use, a cost-effective basic model is ideal. There’s no need to chase extra features; focus on ensuring the machine’s core functions are stable and free from failure.

- Medium-Frequency Use: For small to medium-sized repair shops that handle daily orders, opt for a mid-range model. Pay special attention to the durability and ease of maintenance of the walnut media circulation system to reduce downtime and improve operational efficiency.

- High-Frequency Use: Large auto repair shops or chain stores performing mass cleaning operations should go for high-end industrial walnut blasting equipment. Look for features like overload protection, automatic sand cleaning, and frequency adjustment to ensure long-term stable operation and extend the machine’s service life.

Walnut Blasting Machine for Sale

Focus on Core Specifications: These Parameters Directly Determine “How Well It Works”

Power System: The “Heart” of Cleaning Efficiency

Walnut Media Circulation System: The “Key” to Long-Term Costs

Walnut media is a consumable, so a high-quality circulation system will recycle, filter, and reuse it, drastically reducing operational costs. For medium and high-frequency uses, consider these features:

- Basic Models (No Circulation/Simple Circulation): These are only suitable for low-frequency use as the walnut media is used once and thrown away. Over time, the cost of walnut media might exceed the machine’s cost.

- Mid-to-High-End Models (Multi-layer Filtration Circulation): Look for machines with a “filter screen + cyclone separation” structure. This will efficiently separate carbon, oil, and other contaminants, recycling walnut media with a recovery efficiency of ≥80% (acceptable) and ≥90% (excellent).

- Important Tip: Choose walnut blasting machines with stainless steel filters, as they are less likely to clog, less prone to damage, and can be easily removed for cleaning, reducing maintenance time.

Air Pressure and Media Flow: Balancing Cleaning Effectiveness and Part Safety

Air pressure determines the impact force of the walnut media, while the media flow affects cleaning speed. Both need to be precisely matched. If the air pressure is too low, stubborn carbon won’t be cleaned off, but if it’s too high or the media flow is excessive, it could scratch engine metal surfaces or damage the valve seals.

Important Tip: Choose walnut blasting equipment with adjustable air pressure and media flow. This feature allows the machine to adapt to multiple cleaning scenarios, saving you from purchasing multiple models.

Media Capacity Design: Is It Sufficient? How Good Is the Seal?

The media storage tank is a key component. Pay attention to its capacity and sealing, as both directly affect convenience and environmental protection:

- Capacity: Small models ≤ 5L (for small part cleaning, no frequent media refills required), Medium models 5–15L (for car engine cleaning, enough for daily orders).

- Sealing: The machine must have designs to prevent media leakage and dust dispersion. This ensures walnut media is not wasted and protects the operator’s respiratory health, while also meeting the environmental compliance requirements of the repair shop.

Scene Adaptation: Make the Equipment “Fit” into Your Workflow

Once the core specifications are covered, match the machine with your operating environment, usage method, and available space. This will make the machine more convenient and improve work efficiency.

- Mobile Repair/Small Spaces: Choose a portable walnut blasting tool with swivel wheels and a handle for easy transport. Keep the weight ≤ 20kg, and opt for air-powered models (no need for fixed power connections, suitable for outdoor work).

- Fixed Station Use: Choose a stationary or floor-mounted model. These machines tend to be more stable, and their media circulation system and storage tank are more complete. They’re ideal for high-frequency, continuous operations and can be fixed on a workbench or wall to save space.

- Single-Person Operation (Most Auto Repair Scenarios): Choose a single-person operation model with an integrated spray gun and media control system. Design a simple, easy-to-understand control panel to help newcomers get started quickly.

After-Sales and Consumables: Long-Term Use “Guarantee”

Walnut blasting machines are industrial devices, and maintenance and part replacement will be necessary over time. After-sales service and consumables compatibility directly affect the long-term user experience, so don’t overlook these aspects.

- After-Sales Service: Check the warranty period and the quality of the support. Look for at least 1-year machine warranty and 2 years on core parts (motor, air pump, circulation system). A longer warranty gives peace of mind.

- Consumable Supply: Confirm that the manufacturer provides long-term supply of walnut media, spray nozzles, sand tubes, filters, and other consumables at reasonable prices. You don’t want to be in a situation where parts are unavailable, leading to costly downtime.

- Support: Opt for brands that provide on-site installation/commissioning (for large industrial models) or remote technical support. These brands will resolve issues quickly, so you won’t have to go through trial and error.

Recommended High-Quality Models: AUTOOL Walnut Blasting Machine – A Safe Bet

Now that you understand how to select the right walnut blasting machine, you may still be undecided on which brand to choose. Based on market reputation, configuration, after-sales support, and other factors, we highly recommend AUTOOL walnut blasting machines. As a well-known brand in automotive repair equipment, AUTOOL’s models perfectly meet the selection criteria and can fit various shop sizes, whether it’s a personal garage, a medium-sized shop, or a large chain store.

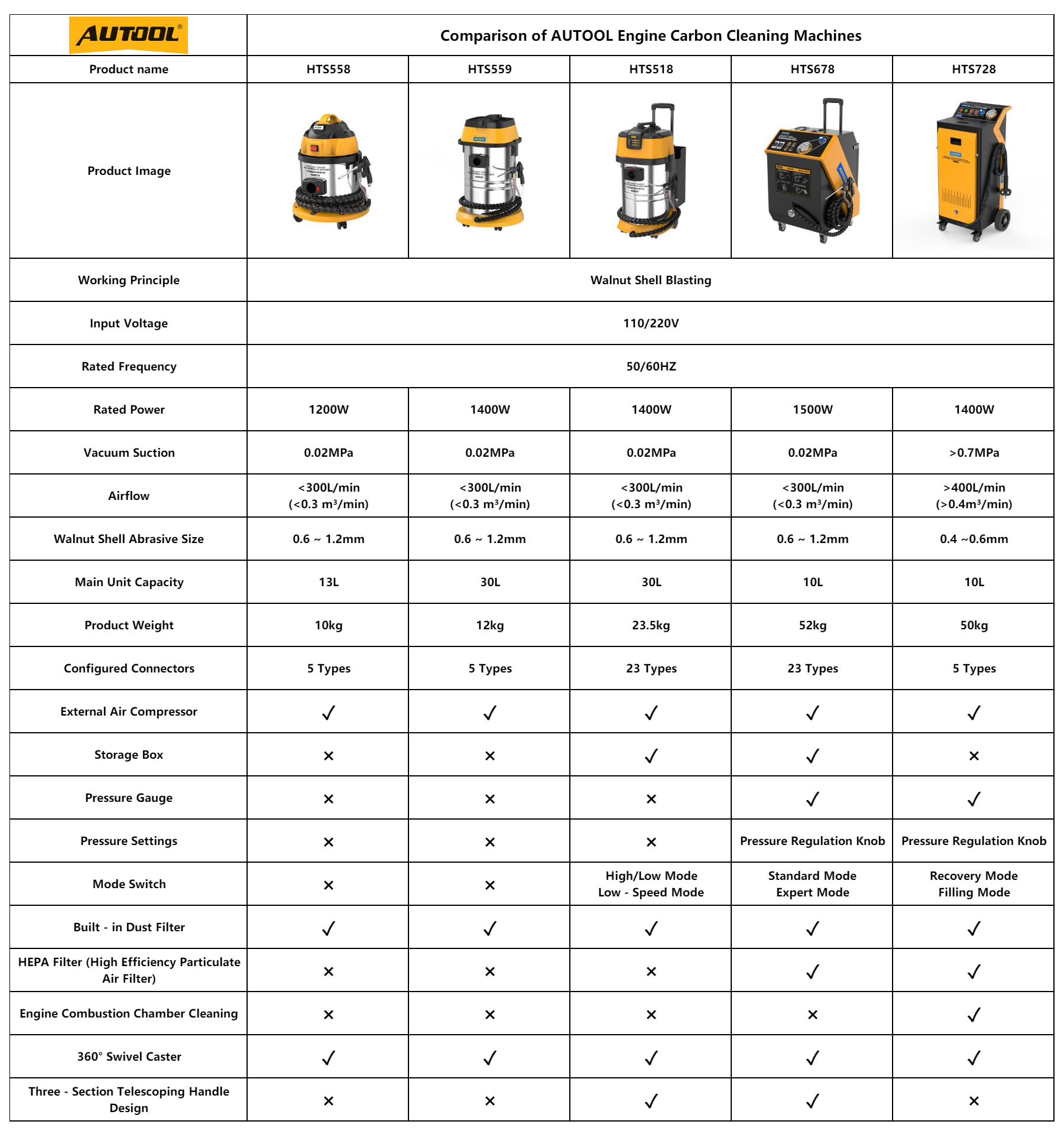

AUTOOL Popular Model Recommendations:

- Best for Beginners: HTS558: Ideal for low-frequency use, personal shops, or part-time repair businesses. The compact design, lightweight, and essential features make it a highly cost-effective choice. It uses natural walnut media with no chemical corrosion, making it easy to recycle.

- Best Seller: HTS728: Perfect for medium-to-high-frequency use in small to medium repair shops. It has an efficient circulation system with a walnut media recovery rate of ≥90%, making it user-friendly and compatible with most mainstream vehicles.

Conclusion: Choose the Right Equipment, Make Carbon Cleaning Easier

The key logic for selecting a walnut blasting machine is: first define your needs, then focus on core specifications, followed by adapting to your work environment, and finally, consider after-sales and consumable support. If you follow this approach, you’re unlikely to go wrong.

AUTOOL walnut blasting equipment meets all these criteria and is trusted by many auto repair professionals. Whether you are running a personal shop or a large repair facility, AUTOOL has a model that will suit your needs. If you’re still unsure which model to choose, check out AUTOOL’s series. You’ll definitely find the perfect fit and make engine carbon cleaning more efficient and hassle-free.

👉Contact us now to purchase a walnut blasting machine and enjoy exclusive discounts for new customers!

📩 Contact Us Today:

• WhatsApp: +86 189 2647 7404

• Email: shop@autooltech.com