AUTOOL ATL-4D Two Post Car Lift 4000KG Load Capacity

$9999.00

Price is for reference only. For exact pricing, please contact our online customer service.

For wholesale prices and more discounts click here.

Please select the correct warehouse before payment. Such as EU users choosing Germany stock will enjoy free shipping and no customs duties (except Serbia and Cyprus).

AUTOOL ATL-4D Two Post Car Lift, 4000KG Load Capacity

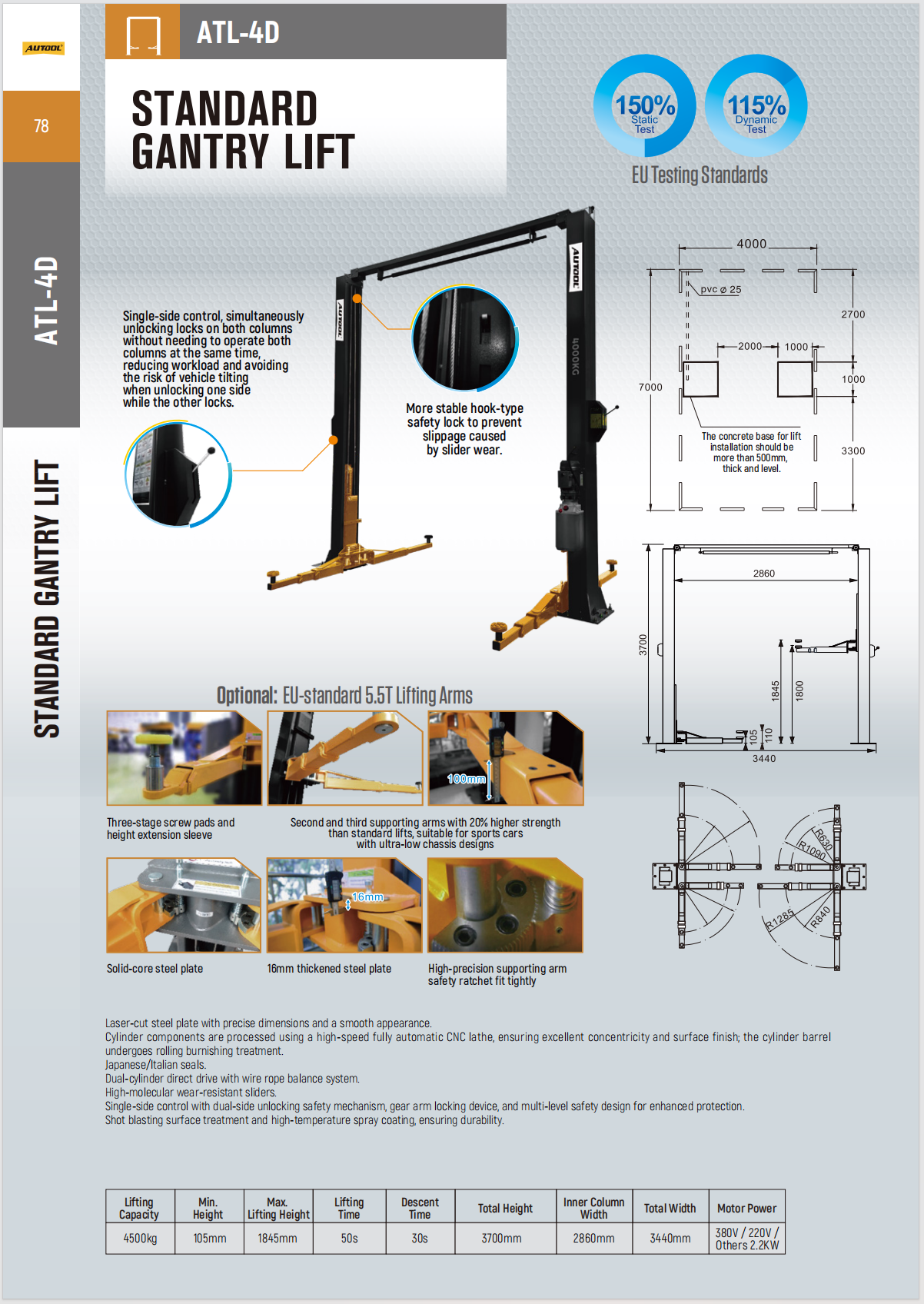

The AUTOOL ATL-4D Two Post Car Lift features single-side control—just operate one side to unlock both columns at the same time. This design makes work faster, simpler, and prevents the vehicle from tilting due to unsafe unlocking.

The frame is built with strong steel tubing and precisely laser-cut plates. Uses a dual-cylinder direct-drive hydraulic system with high-precision components and durable Japanese or Italian seals for smooth, quiet, long-lasting performance.

Equipped with wear-resistant sliding blocks, the symmetric two-post design lifts SUVs, vans, pickups, and light trucks steadily and evenly. It gives ample space to work underneath safely, helping your workshop run more efficiently and professionally.

Note: For ATL-4D, ATL-4.5D, and ATL-4.5DW models that require an additional budget for electronic unlocking, please contact us for consultation.

AUTOOL 2 Post Garage lift’s Features

Core Technology | Precision Manufacturing, Solid Foundation:

AUTOOL crafts the two-post lift’s main structure from laser‑precision steel plates. This process ensures tight dimensional accuracy and seamless assembly. We shot blast and high-temperature coat all steel parts after welding to create a durable, corrosion- and scratch-resistant finish.

- Core System | Precision Drive, Enduring Performance: The equipment lifts loads using a chainless dual-cylinder direct-drive hydraulic system and a synchronized steel cable balance mechanism. This integrated design ensures exceptionally smooth, stable, and synchronized operation throughout the lifting process. By replacing chains with hydraulic cylinders for direct force transfer, the system avoids wear and failure risks, improving safety, durability, and long-term reliability.

- Precision Cylinders: We machine key hydraulic cylinder parts with fully automated CNC lathes to ensure precise coaxial alignment and a smooth surface finish. The inner walls of the cylinder barrels undergo a roller burnishing process, significantly reducing friction and wear during piston movement. This contributes to quieter operation and extends the service life of the hydraulic system.

- Critical Sealing: We fit all key hydraulic sealing points with high-performance Japanese or Italian seals. These seals maintain reliable performance under long-term high-pressure and frequent cycling conditions, effectively preventing oil leakage.

- Wear-Resistant Design: The column guide sections are equipped with polymer composite wear-resistant slide blocks. This self-lubricating material effectively reduces metal-to-metal friction, minimizes operational noise during long-term load lifting, and simplifies future maintenance tasks.

Safety Design | Logical Control, Mechanical Assurance:

-

Unilateral Synchronization Control: Operators only need to work from either column side to simultaneously control and release the mechanical safety locks on both sides. This design simplifies operational steps and fundamentally eliminates the risk of vehicle tilting caused by single-sided misoperation or unsynchronized unlocking.

-

Multiple Mechanical Locking: The equipment is equipped with robust rack‑and‑pinion mechanical locking devices interlocked with the electrical system. At any set height, the mechanical lock backs up the hydraulics, providing stable, reliable protection for people working under the vehicle.

Detailed product data for AUTOOL ATL-4D

Packing List

AUTOOL ATL-4D Two Post Car Lift 4000KG Load Capacity

AUTOOL ATL-4D Two Post Car Lift 4000KG Load Capacity

Reviews

There are no reviews yet