AUTOOL HTS728 Walnut Blasting Machine Expert-Grade Carbon Cleaning Machine

$2895.00 Original price was: $2895.00.$2399.00Current price is: $2399.00.

- Built-in Pressure Pump: High-pressure blasting for efficient cleaning.

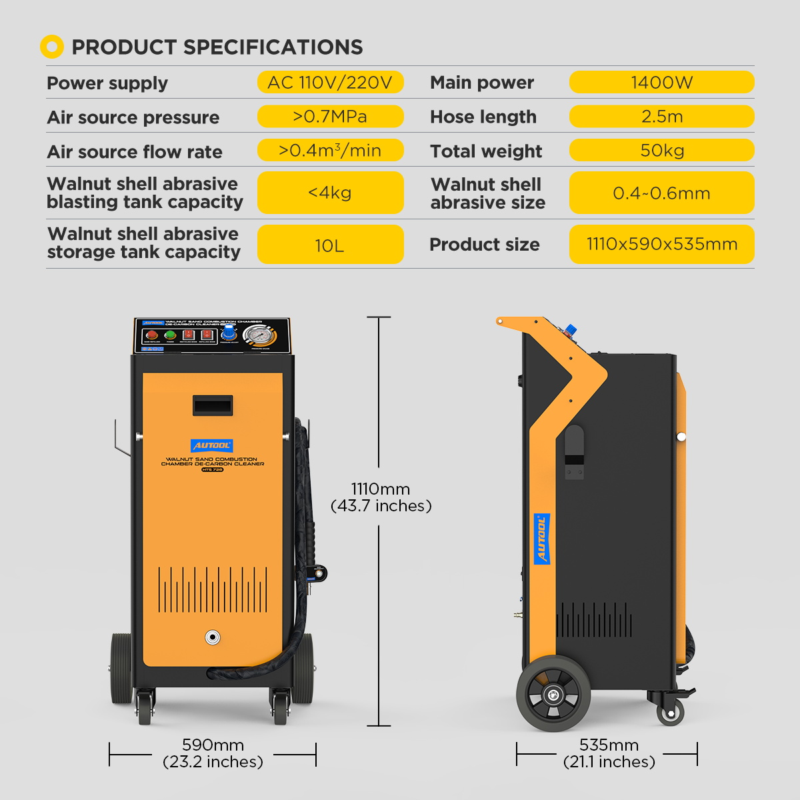

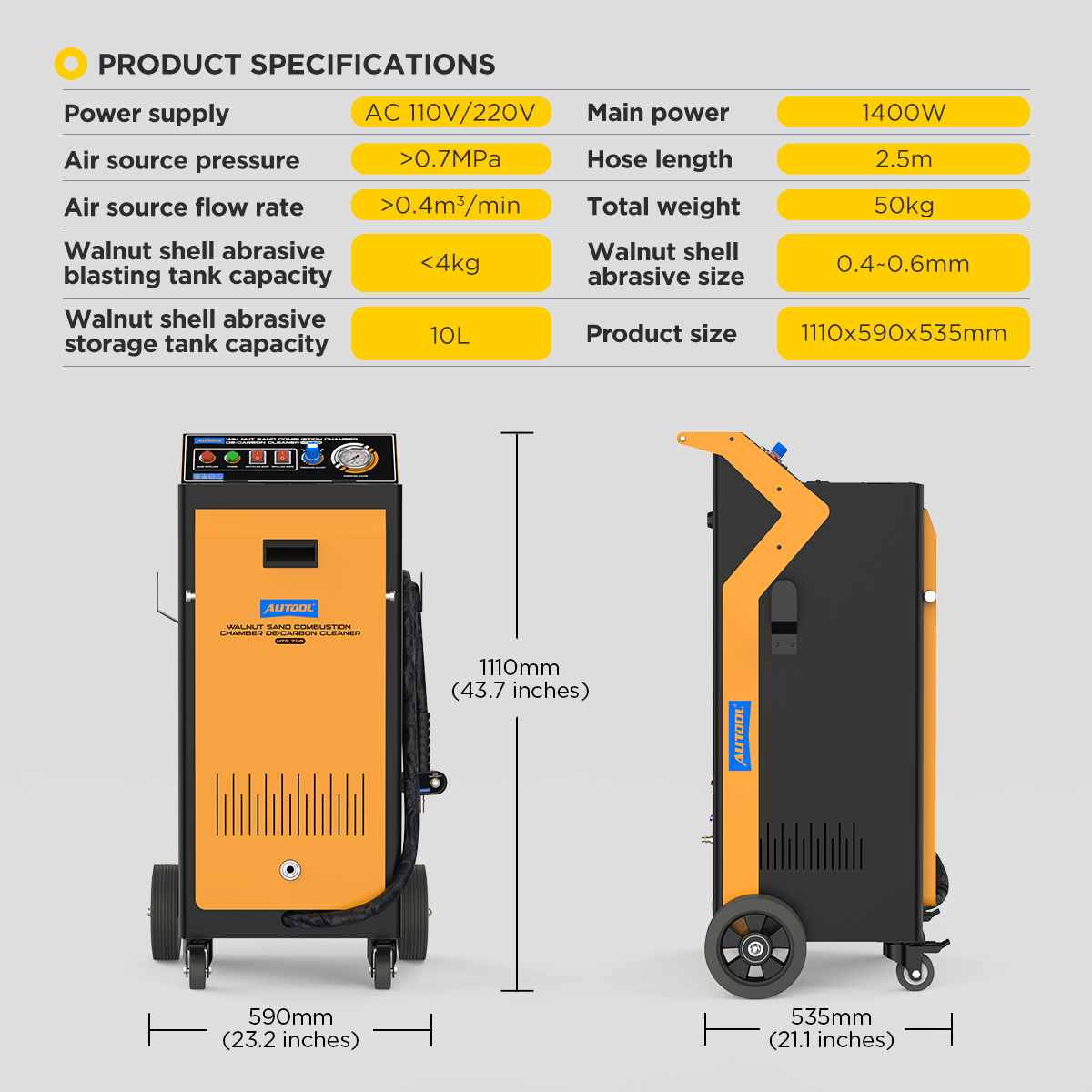

- 1400W Powerful Motor: Strong suction and stable performance.

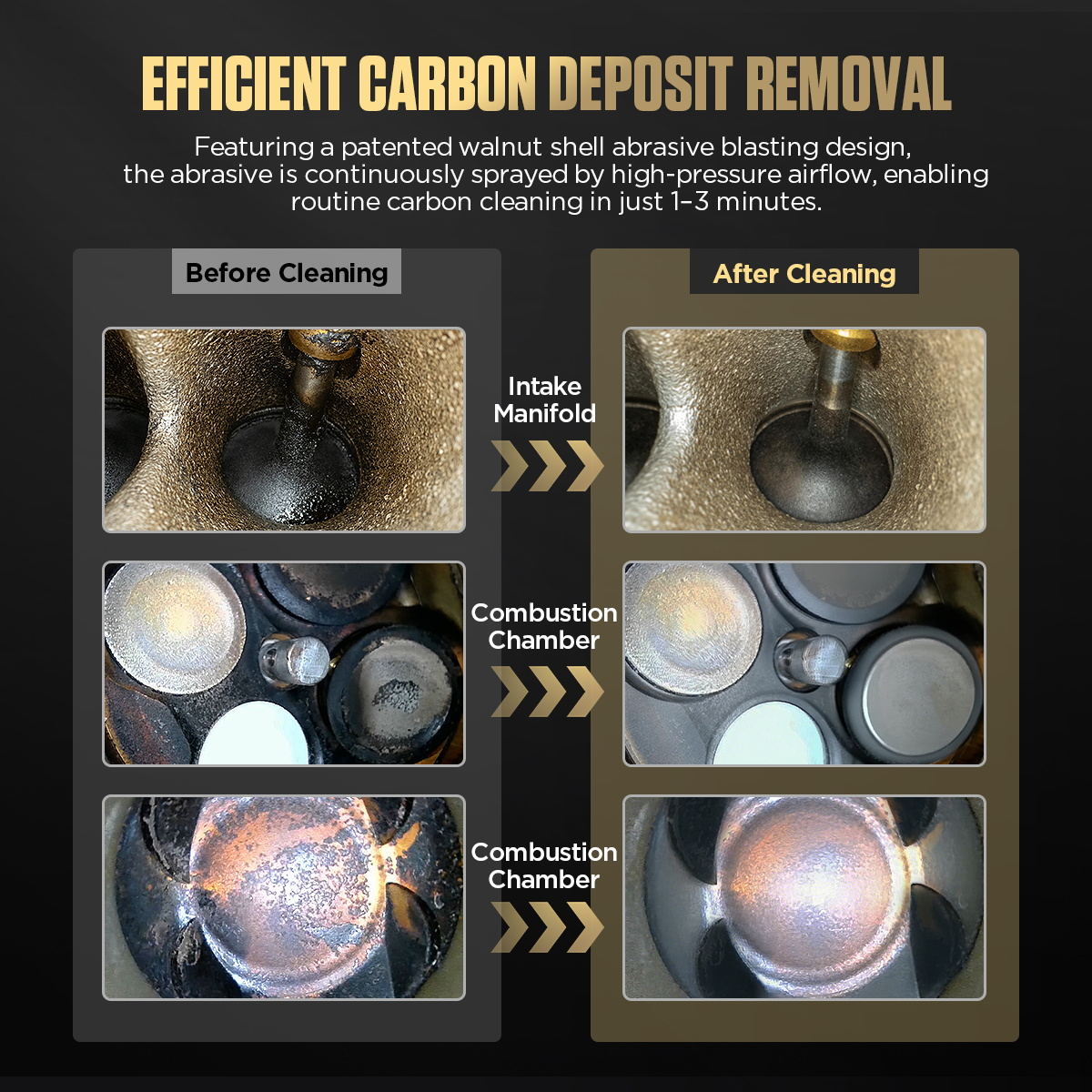

- No Disassembly Needed: Cleans combustion chamber, intake manifold, and valves directly.

- HEPA Filter System: Separates carbon and walnut media for reuse.

- 23PCS Adapters: Fits almost all car models.

- Fine Walnut Media (0.4–0.6mm): More precise and safer cleaning.

For wholesale prices and more discounts click here.

Please select the correct warehouse before payment. Such as EU users choosing Germany stock will enjoy free shipping and no customs duties (except Serbia and Cyprus).

AUTOOL HTS728 Intake Valve Walnut Blasting Machine Expert-Grade Carbon Cleaning Machine for Professional Use 2025 Newest Model

- Walnut sand comes from walnut shells; after workers break the shells, they subject them to strict screening and classification processes. Manufacturers then process this material to create a walnut-derived extract that acts as an effective metal polishing medium. Additionally, walnut sand boasts high hardness, pressure resistance, and wear resistance, and features a microporous surface. This unique structure endows it with strong adsorption and sewage interception capabilities, while the material itself causes no corrosion or pollution to workpieces or the environment.

- Using walnut sand as an abrasive will not damage the workpiece’s surface or harm the engine when cleaning carbon deposits. The cleaning effect is remarkable, and the cost is low.

- The walnut shell abrasive size should be between 0.4~0.6 mm. Under normal conditions, walnut shell abrasive can be reused 5~10 times.

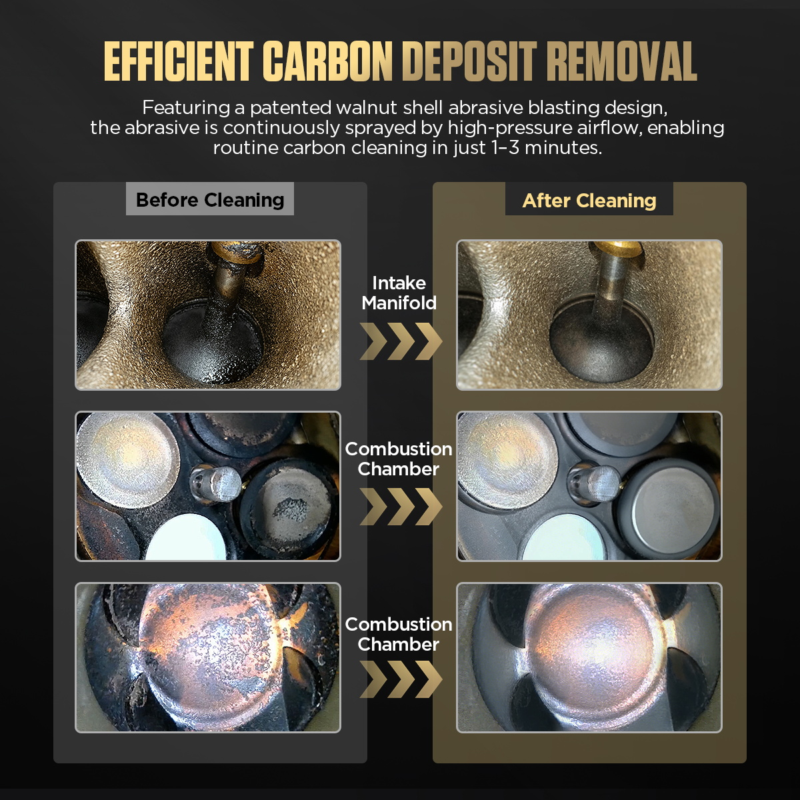

- Some hydrocarbon olefin residues attach to the engine intake and cylinder when the fuel does not burn completely. It residues change into a hard black shell in high-temperature conditions, called carbon deposition.

- Carbon deposition will decrease the air-fuel ratio, cut down engine output power, increase fuel consumption, engine drastic shake on idle status all the thing will hurt the engine deeply. So normally we should clean carbon deposition after every 40000-50000 kilometer trip.

- Air pressure up to 0.7mpa, 6bar or more air pressure.

- We recommend using an air compressor equipped with a dryer filter to effectively prevent moisture buildup, which can cause walnut shell media to clump and result in poor blasting performance.

- Typically, clean each manifold port for about 2 minutes, then stop to check the cleaning results.

- Ensure that all uncleaned manifold ports are sealed before cleaning to prevent walnut shell abrasive from entering unintended areas.

- Do not clean a manifold port if the valves are not closed. When reaching such a port, rotate the crankshaft to close the valves before proceeding.

- After carbon removal, use an air blow gun to blow out any remaining walnut shell abrasive particles.

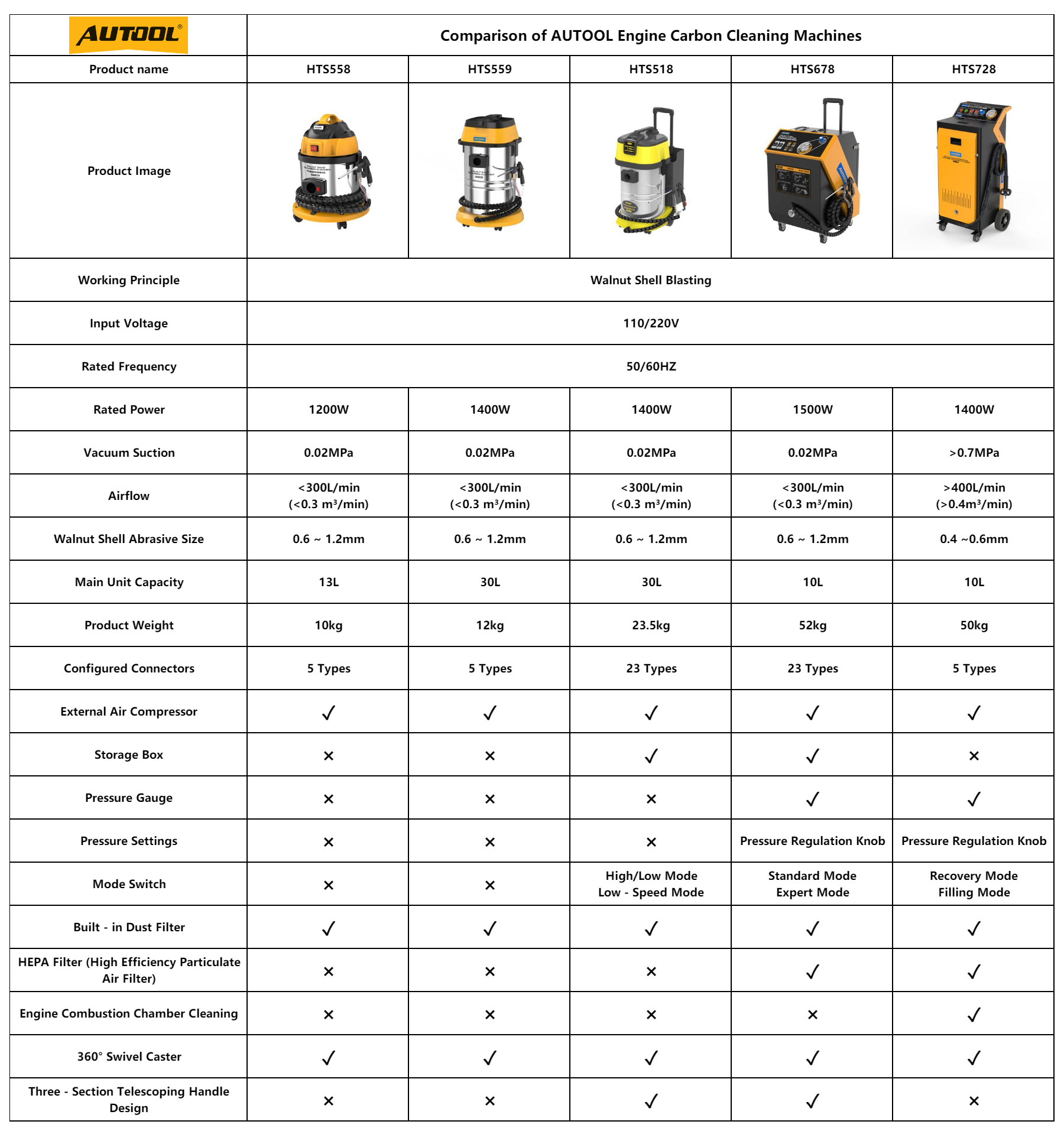

What Is The Difference Between AUTOOL Walnut Blasting Machine?

How to Choose a Walnut Shell Blasting Machine?

The AUTOOL HTS678 features a rated power of 1500W and is equipped with a high-efficiency particulate air (HEPA) filter, thus ensuring a cleaner working environment. Additionally, this model incorporates a three-section telescoping handle design for ease of operation and mobility, and furthermore offers two operating modes—Standard Mode and Expert Mode—to accommodate different user needs. On top of that, pressure regulation is conveniently controlled via a dedicated knob, and to ensure operational safety, the machine is fitted with a pressure gauge for real-time monitoring.

In contrast, the AUTOOL HTS728 Walnut Shell Sand Blaster is an upgraded version of the HTS678. This model utilizes finer walnut shell abrasive (0.4–0.6mm), thereby excelling at more precise engine cleaning tasks. Beyond that, its most significant difference lies in the AUTOOL HTS728 supporting engine combustion chamber cleaning.

The AUTOOL HTS558 Walnut Blasting Machine is the basic model of the walnut blaster, featuring a rated power of 1200W and equipped with 5 types of adapters to meet different user needs. It is highly suitable for individual users or workshops.

The AUTOOL HTS559 Walnut Blasting Equipment is an upgraded version of the HTS558, and it boasts a rated power of 1400W and a 30L main unit capacity, thus offering greater efficiency and durability.

Compared with the HTS559, the AUTOOL HTS518 Walnut Blasting Machine further supports High/Low Mode and Low-Speed Mode, thus allowing users to choose between different cleaning modes according to the application.

All three walnut blasting kit share the same core functionality. In contrast, the main differences lie in power output and main unit capacity, enabling users to select the most suitable model based on their budget and operational requirements.

AUTOOL Walnut Blaster Machine Quick Search

AUTOOL HTS728 Walnut Blasting Tool Features

- Engine Combustion Chamber Cleaning: Blasting cleaning directly into the combustion chamber via the spark plug hole consequently eliminates the need for disassembly.

- Intake Manifold Cleaning: The machine sequentially cleans each intake manifold using blasting, thereby ensuring thorough carbon removal.

- Intake/Exhaust Valve Cleaning: It cleans intake and exhaust valves sequentially with blasting, thus without the need for disassembly.

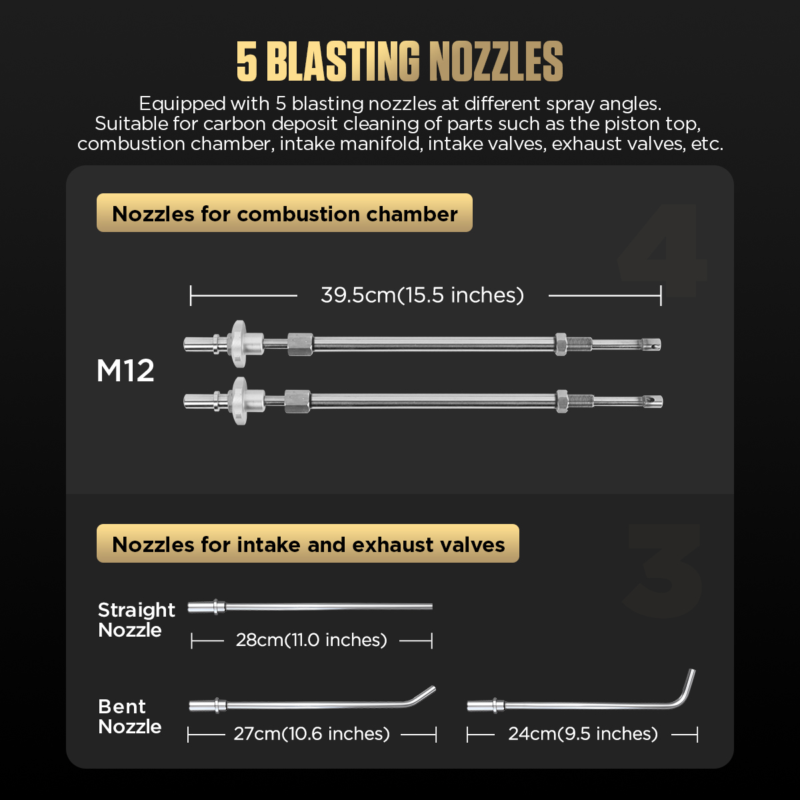

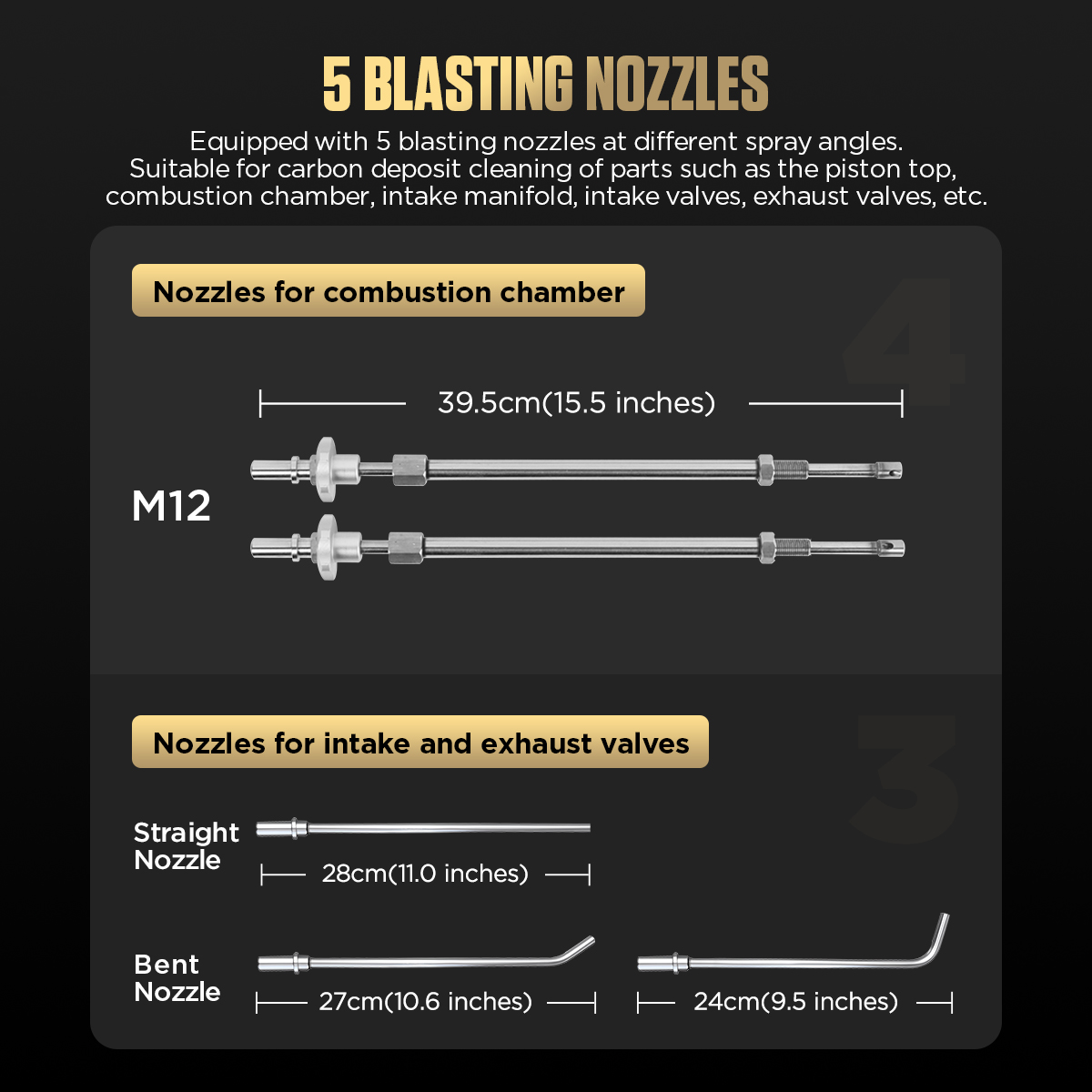

- Multiple Adapters: Equipped with 5 adapters, supporting a variety of vehicle models.

- External Air Source Design: The machine is powered by a 1400W high-performance motor, which uses an external air source to provide continuous power. This enhances the impact force of the walnut shell abrasive, ensuring thorough removal of carbon deposits from the engine pipes.

- Built-in HEPA Filter: The equipment performs spraying and recovery simultaneously. The filter separates walnut shell abrasive from carbon deposits, reuses the abrasive, and prevents residual particles from damaging the high-temperature exhaust system.

- Integrated Design: The walnut shell abrasive is recycled within the equipment, and no manual recovery is required, saving time and effort.

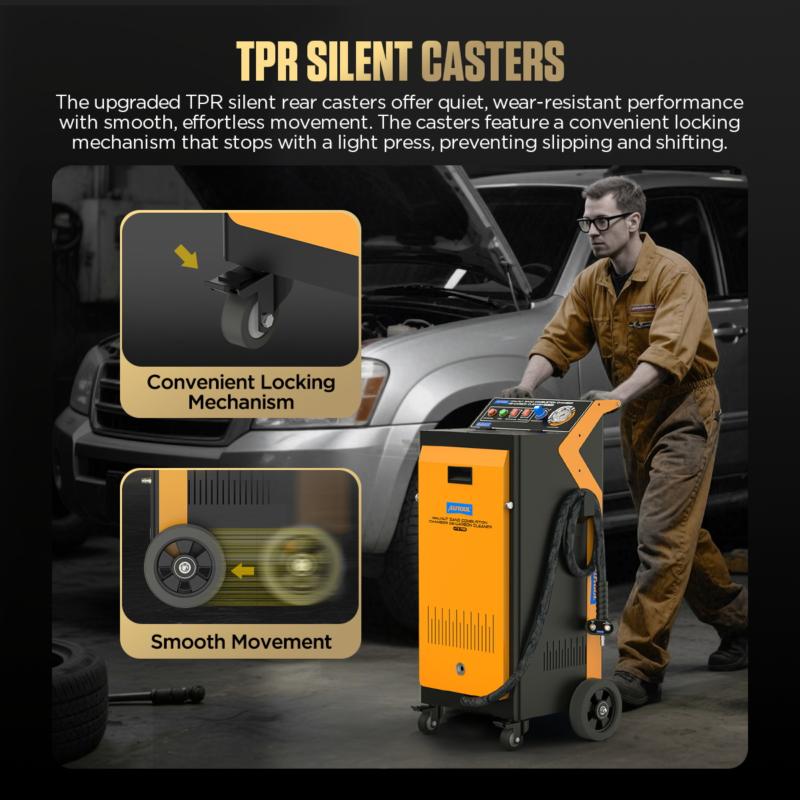

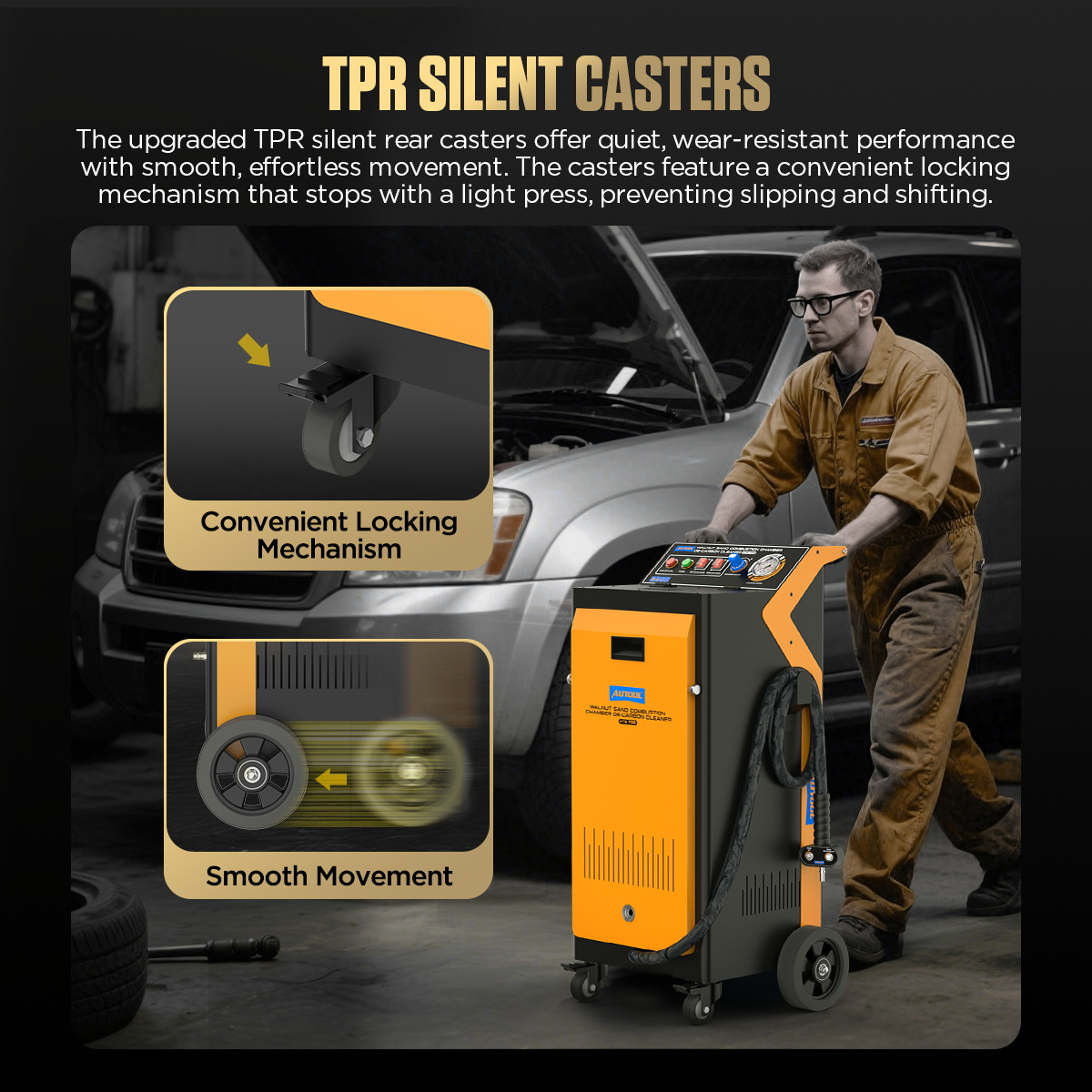

- User-Friendly: Equipped with a swivel caster that can rotate 360°, making it easy to move and operate.

- 3-Year Warranty: For damage caused by non-human factors, we promise to resend parts for free within 3 years.

How To Use the AUTOOL HTS728 Walnut Blasting Machine?

1. Setup

- Place the machine in the working area.

- Take out the recovery hose and connect it to the recovery port.

- Attach the elbow connector to the recovery hose.

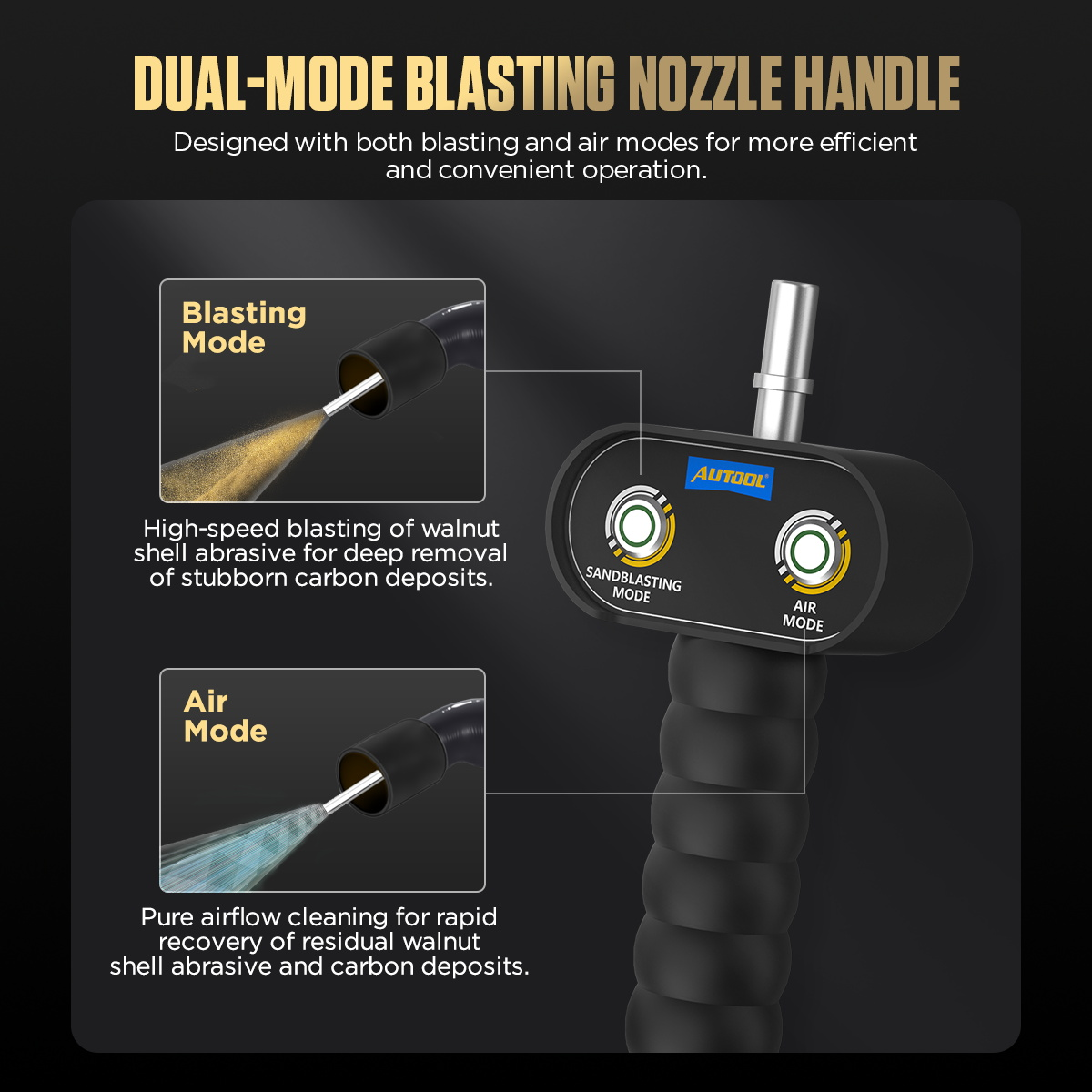

- Connect the sandblasting tube to the spray gun handle.

- Connect the air supply to the air inlet.

- Plug in the power cord and turn on the power switch.

2. Loading Walnut Media

- Make sure the recovery mode is OFF.

- Turn ON the loading mode.

- Add no more than 3.5KG of walnut sand (0.4–0.6mm).

- Brush leftover sand into the loading port if needed.

- Close the top lid and wear safety goggles.

- Turn OFF the loading mode – the pressure will build up (>0.7MPa).

3. Vehicle Preparation

- Remove the spark plugs and intake manifold.

- Check valve positions – make sure valves are closed.

- Seal other intake ports to prevent sand entry.

4. Intake Cleaning

- Insert the sandblasting tube into the intake port.

- Connect the recovery hose to the port and ensure a tight seal.

- Turn ON the recovery mode.

- Open the spray gun valve and adjust direction/depth to clean.

- Clean each port for about 2 minutes.

- Use an air gun to blow out remaining sand.

5. Combustion Chamber Cleaning

- Rotate the crankshaft to close valves.

- Insert the spray gun tube into the elbow connector.

- Connect the combined hose/gun to the combustion chamber port.

- Ensure sealing and start sandblasting.

6. After Cleaning

- Turn off all switches.

- Disconnect hoses and power supply.

- Clean and store the equipment properly.

Walnut Blaster Usage Tips

- Firstly, wear safety goggles during operation to ensure safety. In addition, this will help protect your eyes from debris and any potential hazards.

-

The walnut shell abrasive size should be between 0.4~0.6 mm. Under normal conditions, walnut shell abrasive can be reused 5~10 times.

Packing List

Walnut Blasting Machine Tool FAQs:

A walnut shell sand blaster is a specialized tool that cleans the intake and valves of a car engine using crushed walnut shells as abrasive. It helps remove carbon deposits during automotive maintenance to prevent engine problems.

The walnut blasting machine uses compressed air to shoot crushed walnut shells through a nozzle at high speed; when these shells hit the surface of engine parts, they remove carbon buildup. Additionally, the shells break into small pieces during blasting, thus making them a gentle and effective abrasive for cleaning delicate engine components.

Yes, walnut blasting is a safe and effective way to clean intake and valves on gasoline and diesel engines. Notably, removing the valve cover is crucial for accessing the engine parts and cleaning them properly. However, it’s best to consult a professional before using the machine on your specific vehicle.

Walnut blasting is usually safe, but there are risks if it’s not done properly. Using the correct method helps fix engine problems like hard starts and improves engine performance.

The main risk is breathing in fine walnut shell dust. This can cause breathing problems if you don’t use safety gear. When using the machine, always wear a respirator and goggles to stay protected.

How often you should clean the intake and valves depends on the vehicle’s age, mileage, and driving habits. Most drivers clean them every 30,000–50,000 miles or when they notice reduced engine performance. A professional mechanic can give personalized advice based on your vehicle.

Yes, you can easily find replacement parts and blasting media for walnut blasting machines, and specifically, you can purchase them from the AUTOOL.

Click to quickly contact AUTOOL>

It’s important to use high-quality, original parts made for your machine. In contrast, cheap or fake parts can reduce performance or even damage the machine.

Aside from purchasing replacement parts and media, it is also important to regularly maintain and clean your walnut blasting machine. This will not only extend the life of your machine but also ensure its effectiveness in removing unwanted materials.